Corrective and Preventive

Action Management

Talking with other professionals, I find that there is confusion between these 3 items, corrective action, preventive action and preventive maintenance.

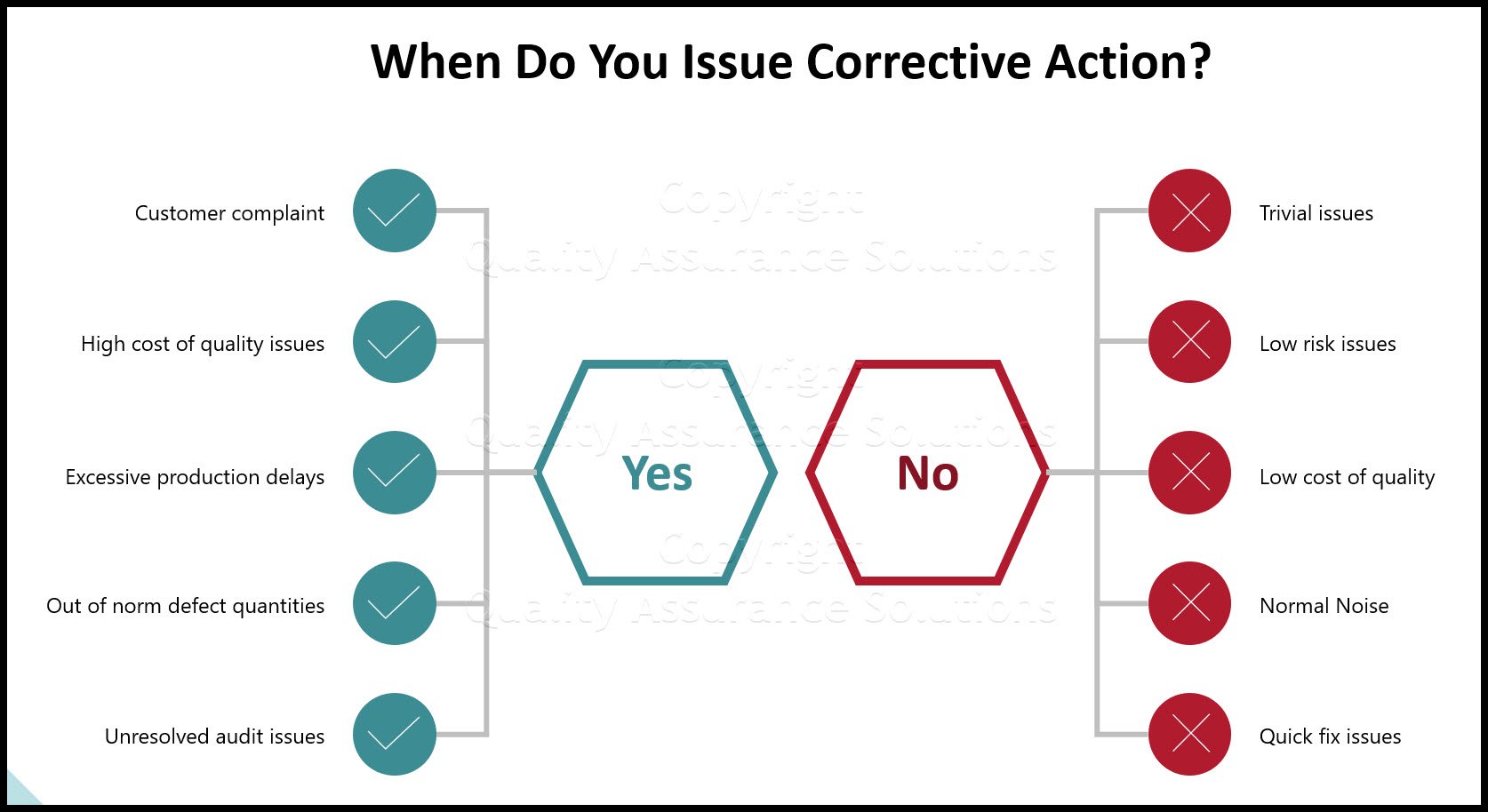

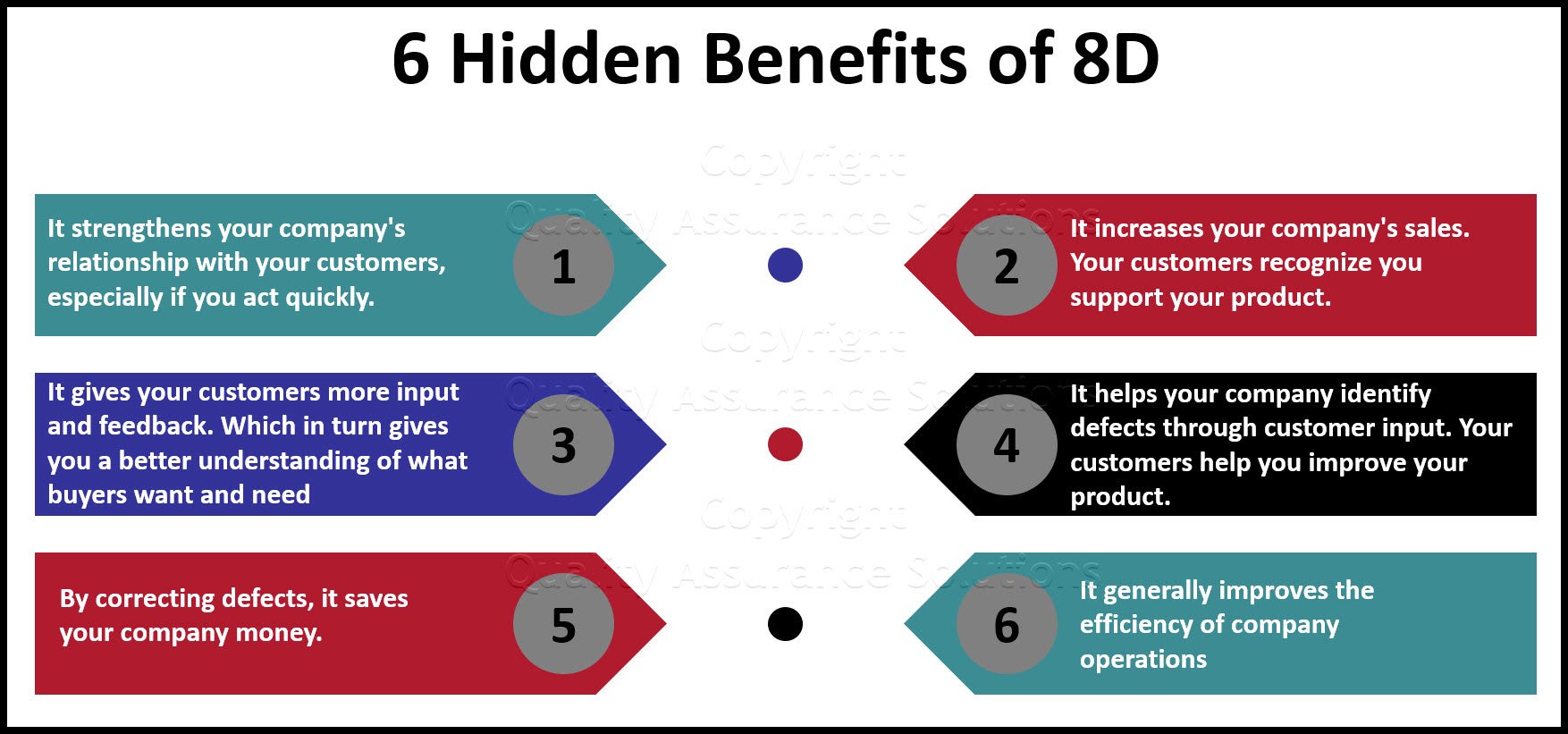

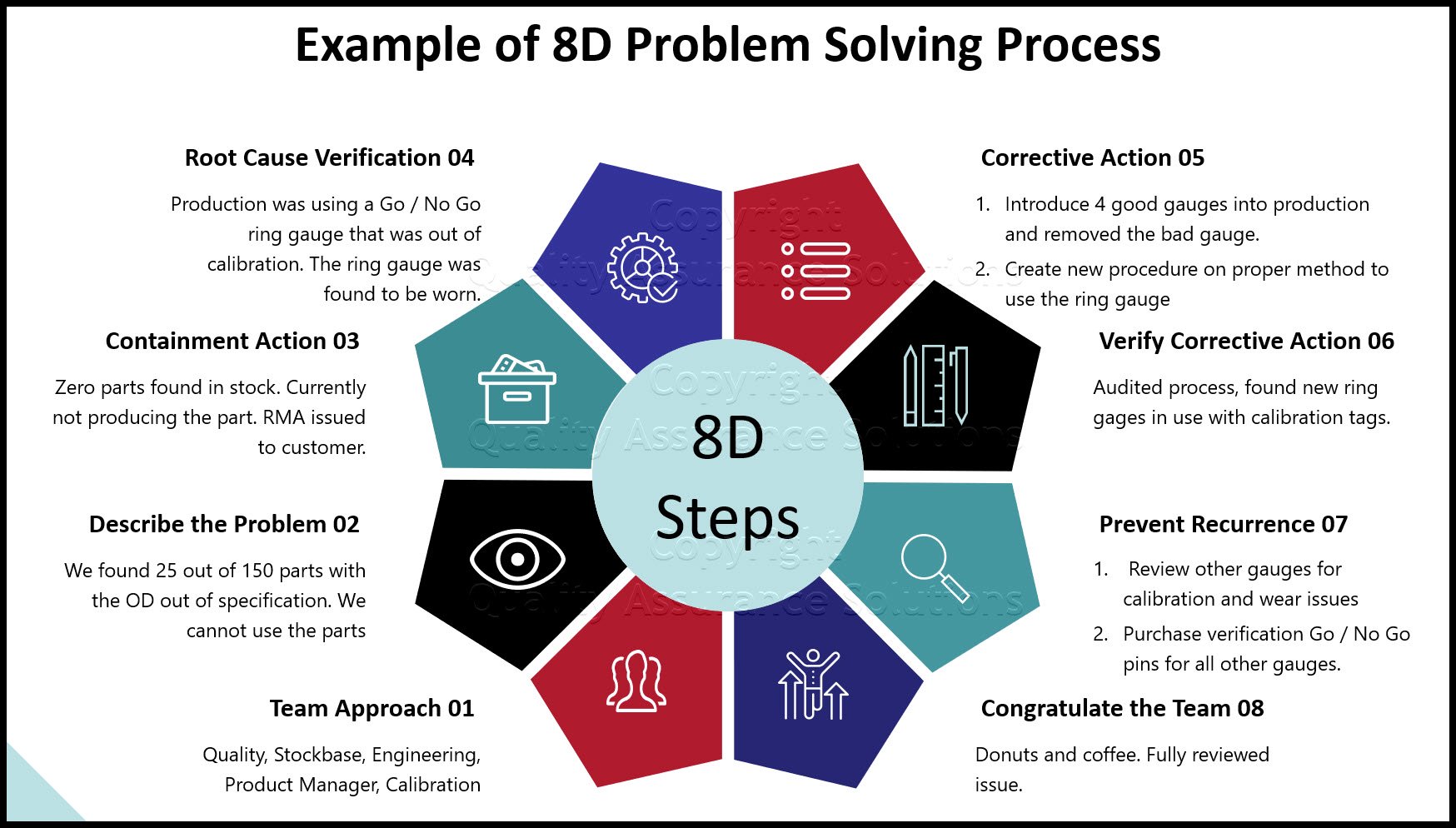

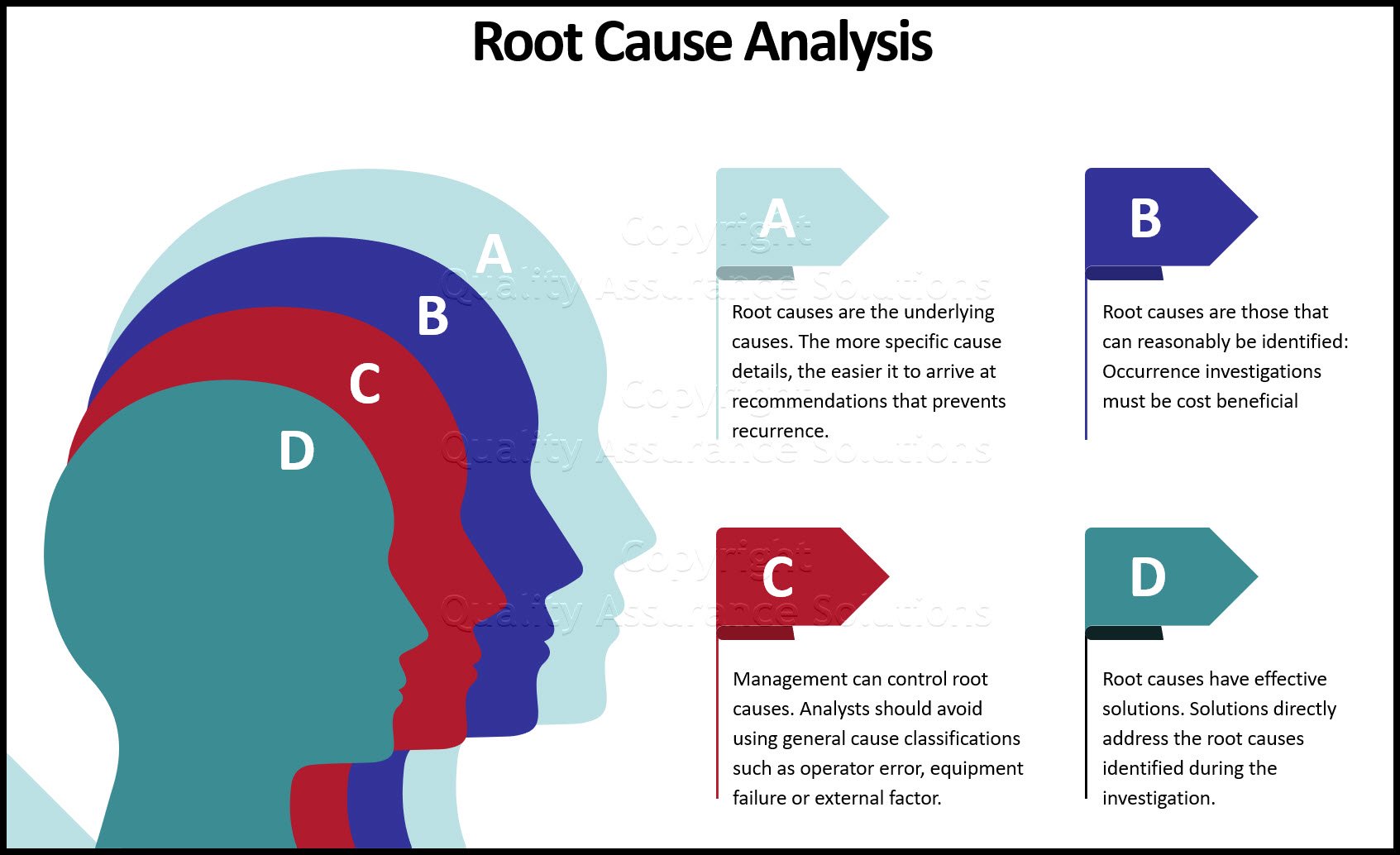

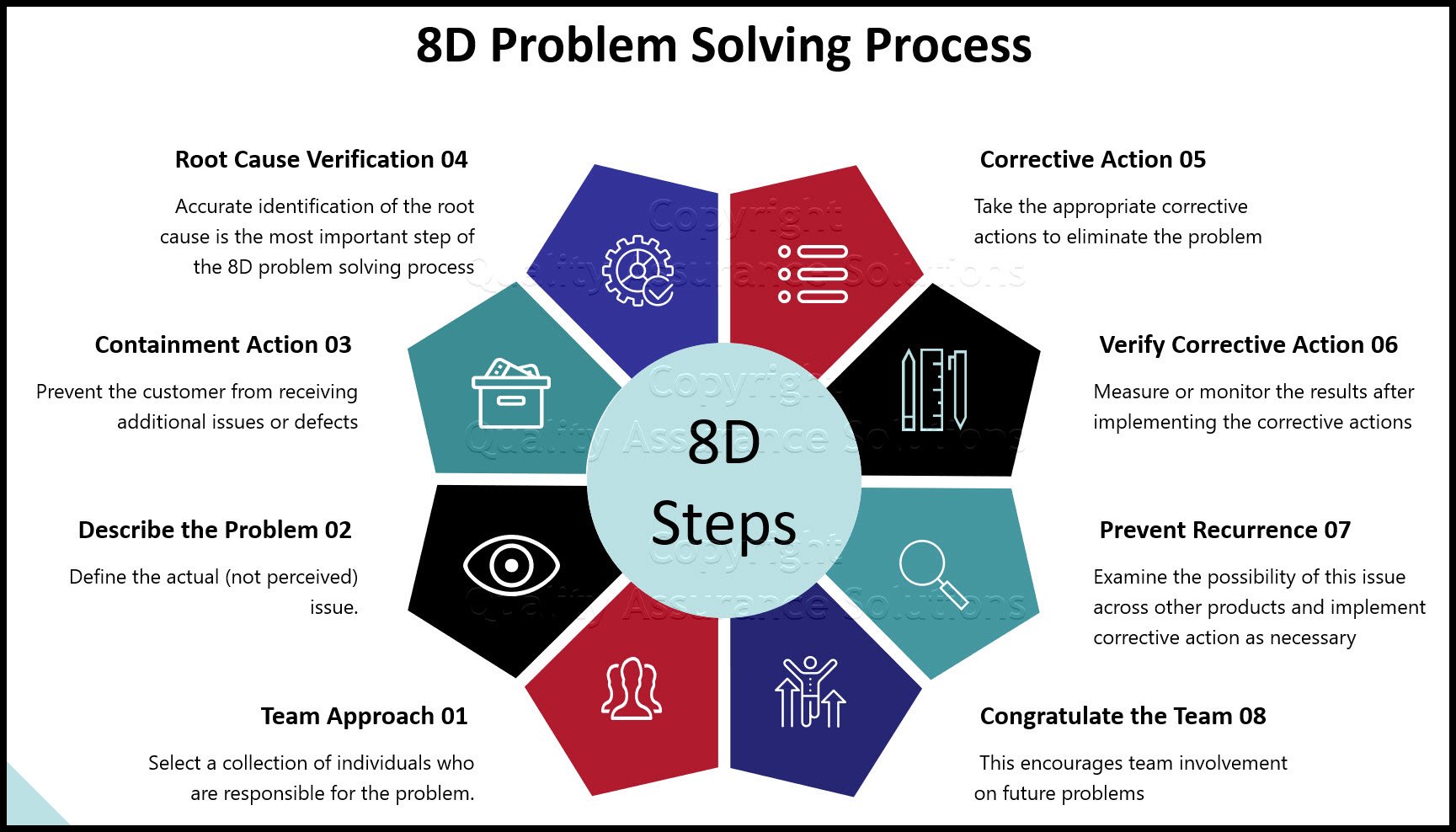

Corrective action treats a nonconformity or problem that has already occurred. The problem exists. The nonconformity lives and needs to be addressed. See corrective action system for ISO 9001 requirements.

Preventive maintenance focuses on the care of machines. It is a system that protects machines from breaking down. ISO 9001 auditors do not look at preventive maintenance as preventive action. Preventive maintenance is important for the infrastructure (resource management) section of the ISO 9001 standard.

Preventive action determines and eliminates potential causes of non conformities. This means the non conformity has not yet happen. If you act to prevent a problem from occurring then this is a preventive action.

The ISO 9001 standard requires you to take preventive action to eliminate potential nonconformities.

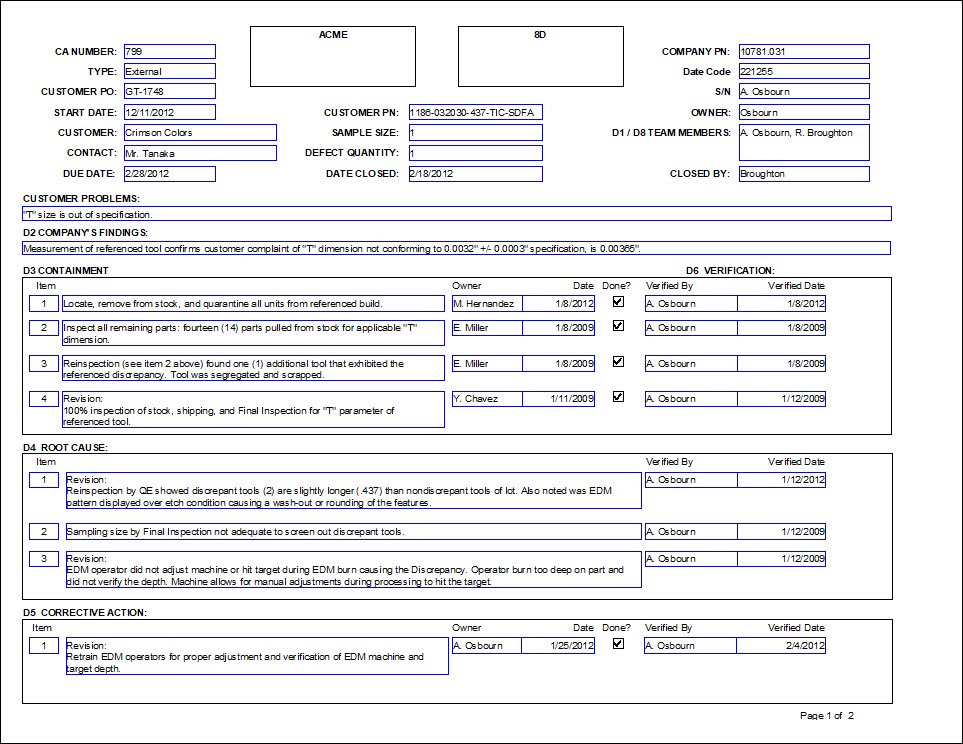

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

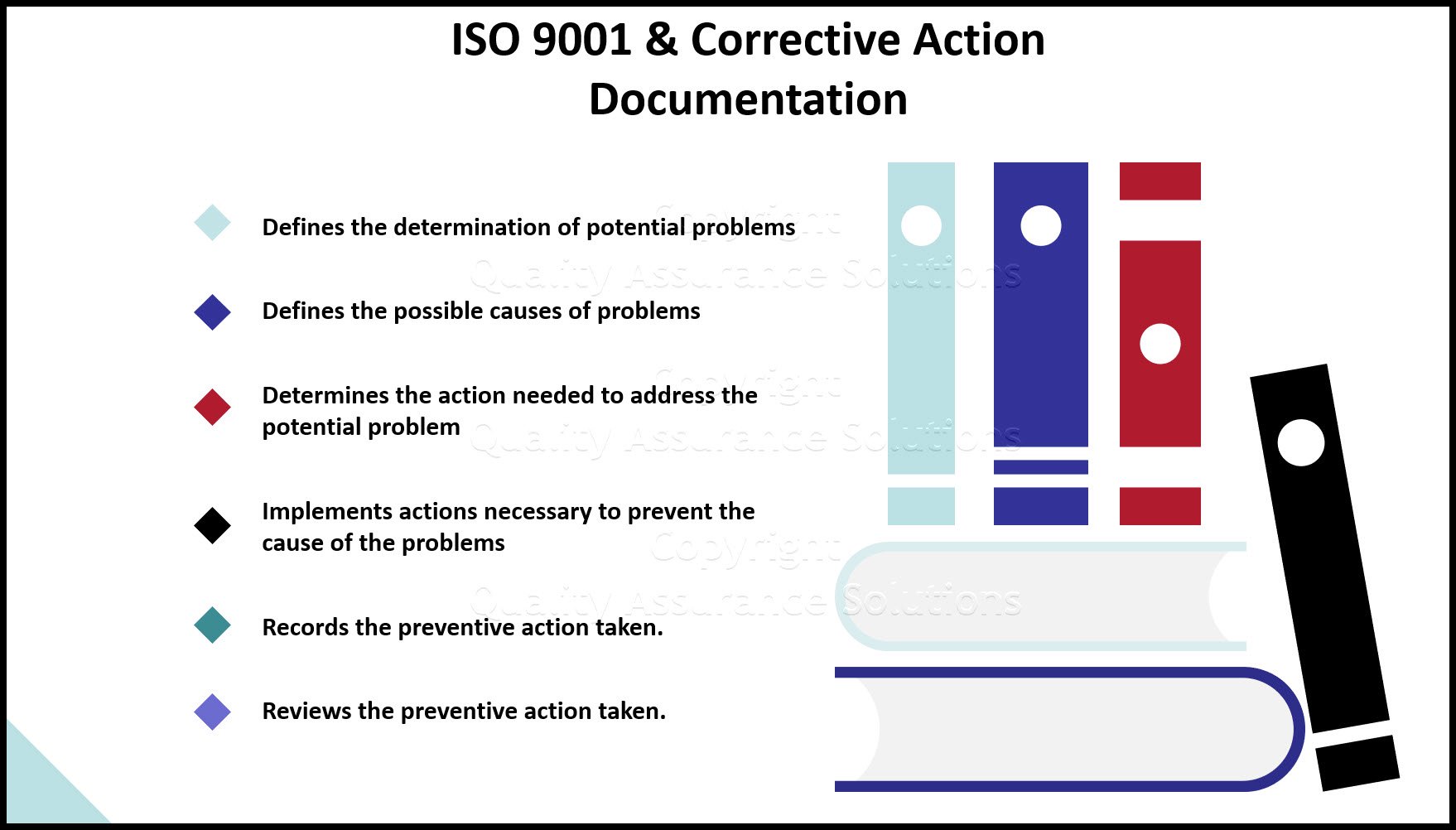

Corrective and Preventive Action Management Documentation

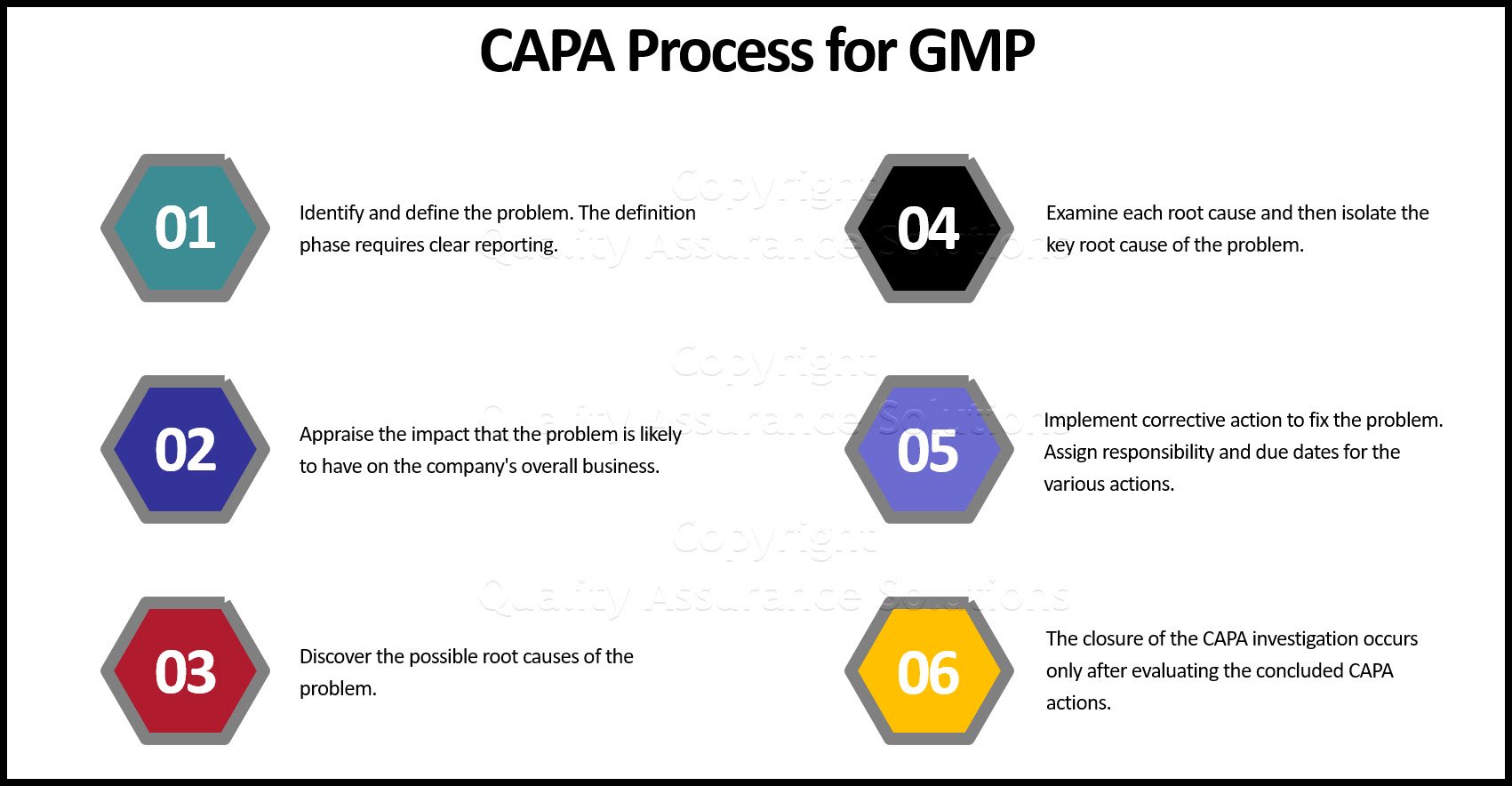

A documented procedure is required for ISO 9001 certification. Within the procedure explain how your company

- defines the determination of potential problems

- defines the possible causes of problems

- determines the action needed to address the potential problem

- implements actions necessary to prevent the cause of the problems

- records the preventive action taken.

- reviews the preventive action taken.

You must have a documented system that covers CAPA management systems. The same document could be used for both. Be sure there are separate sections for corrective action and preventive action.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Preventive Action Examples

- Revising a procedure to reduce the variation between operators is a preventive action. You may find several employee accomplishing the same results but each may have a slightly different method. One method may lead to more nonconformities than another

- Plans to implement a new piece of equipment that reduces the process and product variation is a preventive action.

- Employee certification can be argued as preventive action. By certifying the employee, the employee has proven they fully understand the process and procedures. These skilled employees will prevent non conformities.

- Lessons applied from a previous corrective and preventive action management action could be a preventive action. Lessons learned from a specific corrective action is then applied to similar products or processes. The applications of the learned lessons are preventive actions

A FMEA (Failure Mode Effects and Analysis) can drive preventive action. This is a tool that scores potential failures. Preventive actions will occur by lowering the potential failure scores.

- QAS Home

- Preventive Action

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

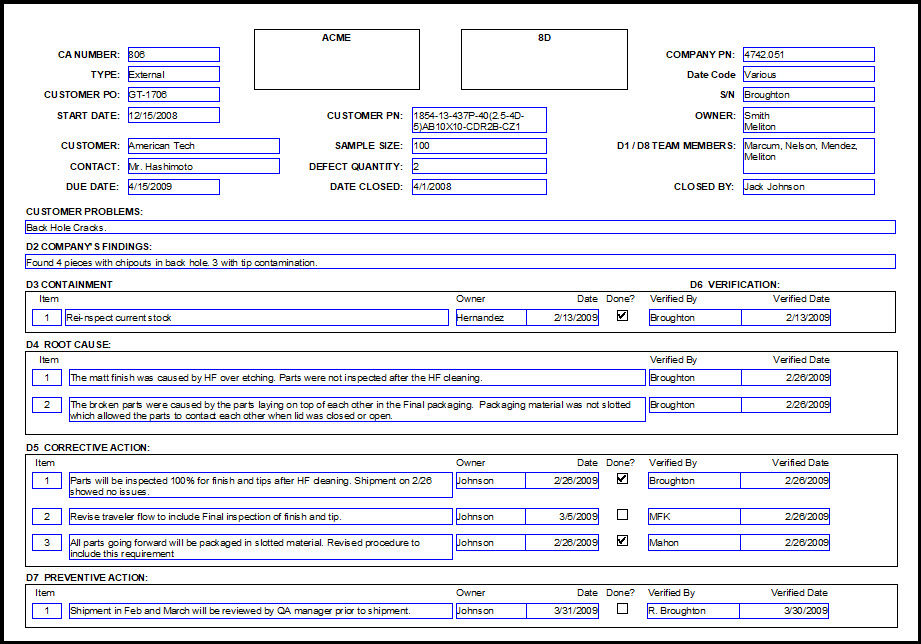

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |