8D Eight Disciplines

8D Eight Disciplines problem solving process...If you don't work in the manufacturing sector, chances are you have never heard of 8D. Though it might sound a bit strange, 8D simply stands for Eight Disciplines. Companies use these global 8D techniques when a customer files a complaint or corrective action. It is commonly used by companies as a way to solve customer relation disputes.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

How exactly does 8D eight disciplines of problem resolution work? Well, when the complaint comes in, the company is often required to complete a problem solving report and forward it to the customer. Because many companies have adopted the 8D system, we offer a popular 8D software program that makes it easy for workers to complete customer reports.

Ford Motor Company specifically designed the 8D process to maintain customer satisfaction and solve internal and external problems.

When companies stick with the 8D program they report that most clients stick with them. Customers with problems are often even grateful that the company dealt with these problems in such an efficient manner. But the company must act quickly, for if they delay there is a good chance the customer walks.

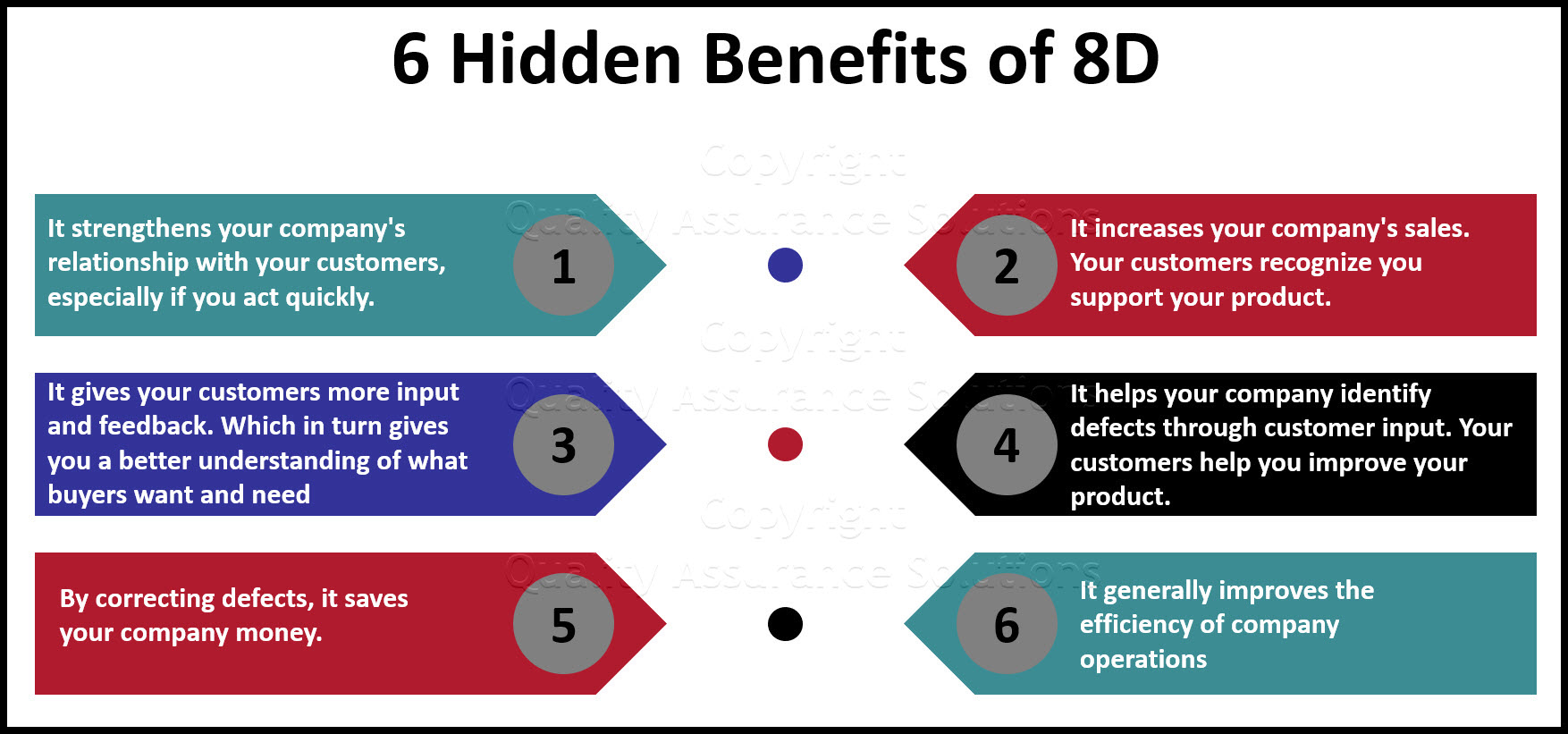

Hidden Benefits to Your Business

- It strengthens your company's relationship with your customers, especially if you act quickly.

- It increases your company's sales. Your customers recognize you support your product.

- It gives your customers more input and feedback. Which in turn gives your company a better understanding of what buyers want and need.

- It helps the your company identify defects through customer input. Your customers help you improve your product.

- By correcting defects, it saves your company money.

- It generally improves the efficiency of company operations.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

8D Software

Why should companies purchase and use 8D software? Well, we've already mentioned several good reasons, but we'll offer up a few more.

To begin with, it saves your employees time writing corrective action reports. It also allows them to store global 8D reports in one place. As we mentioned, the software and system helps improve overall customer service, which undoubtedly increases sales. And lastly, it lets employees compile and present the information in a single report during corrective action meetings.

Who needs 8D Software?

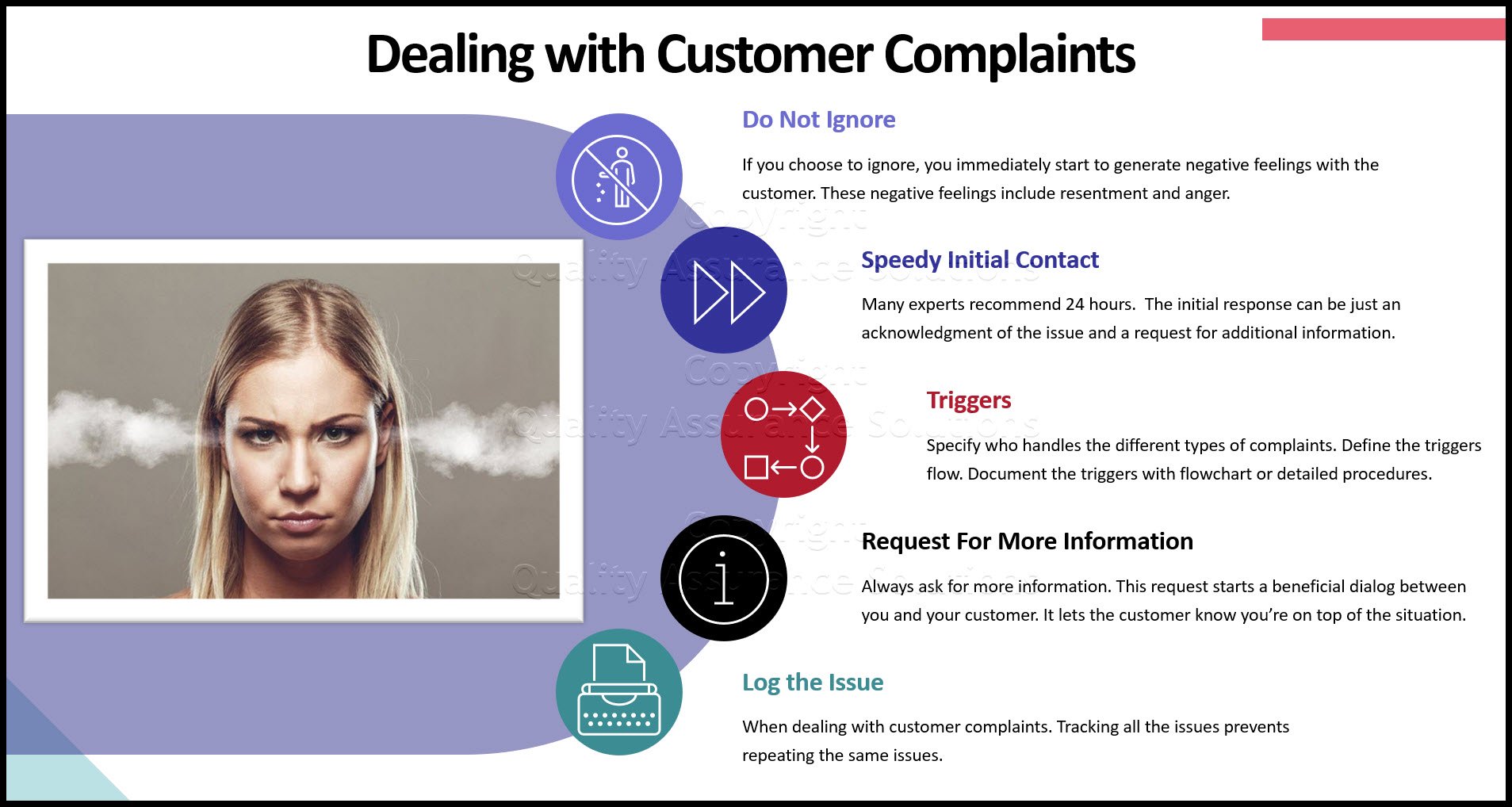

Any company experiencing an increase in customer service complaints should seriously consider 8D eight disciplines problem solving process

software. After all, problems cannot and will not fix themselves. And it is only a matter of time before your start losing customers and revenue.

Many companies, especially smaller ones, often struggle to keep track of corrective actions. And this can be a huge turn off for customers who may end up taking their business elsewhere if the company continues to repeat the same mistakes, or, worse yet, fails to address these errors in a timely manner.

While not a cure-all, 8D eight disciplines software solves many of these problems. It lets you know which clients filed complaints before and if they are experiencing the same problems. This inexpensive software and the included procedure makes your next ISO audit a breeze for the corrective action clause.

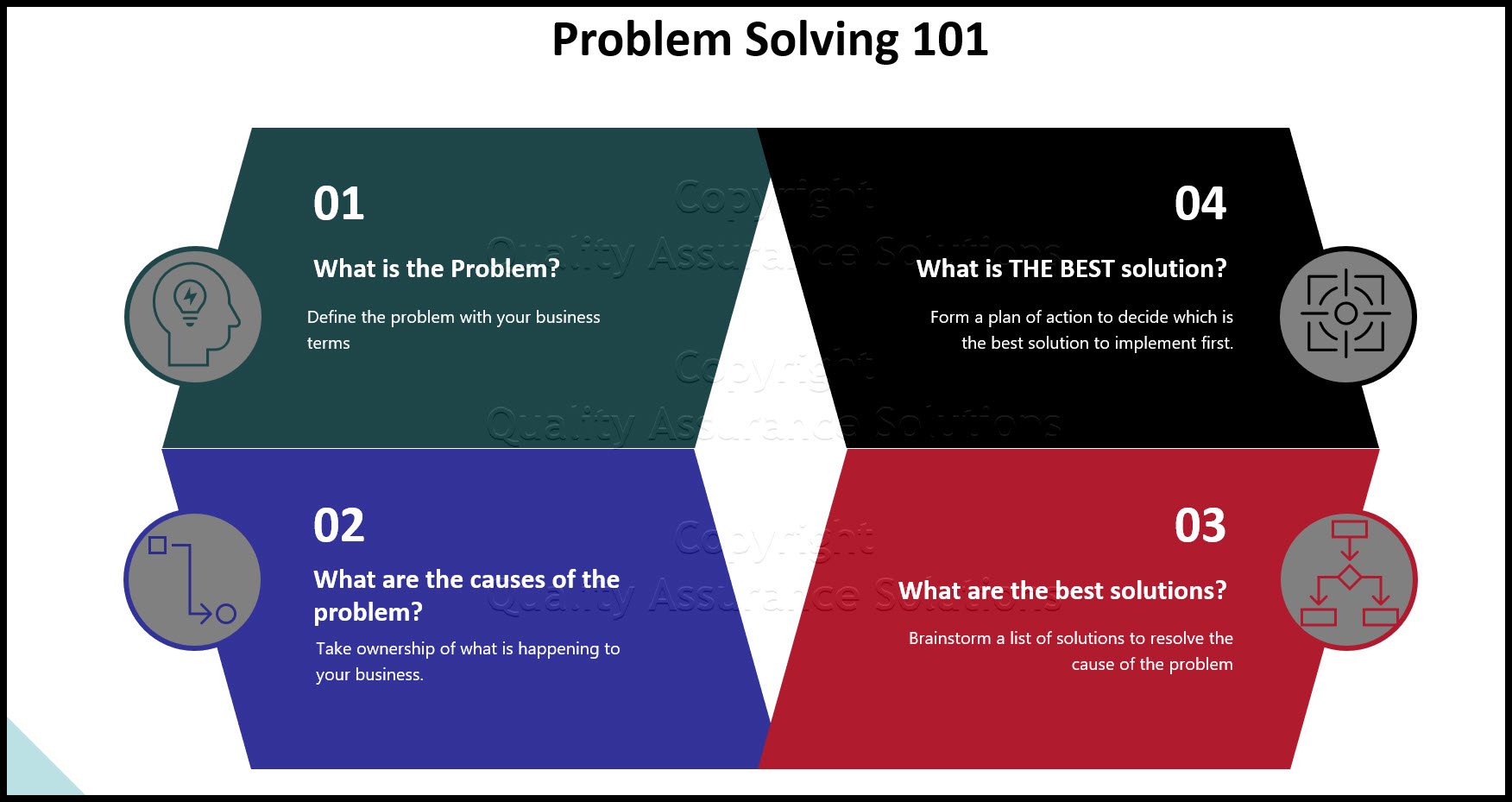

In the next few paragraphs we will take a look at how 8D actually works to help a company resolve its problems.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

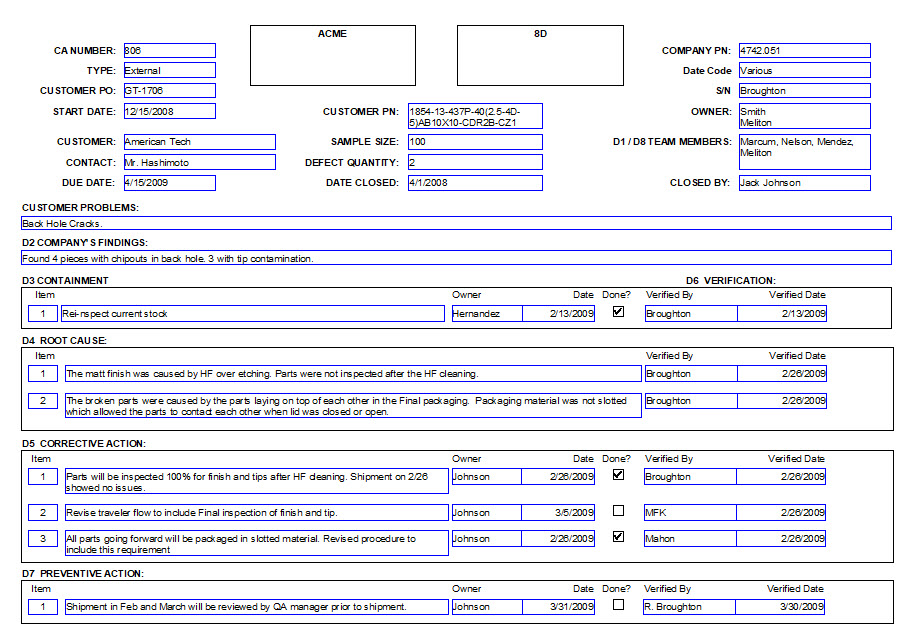

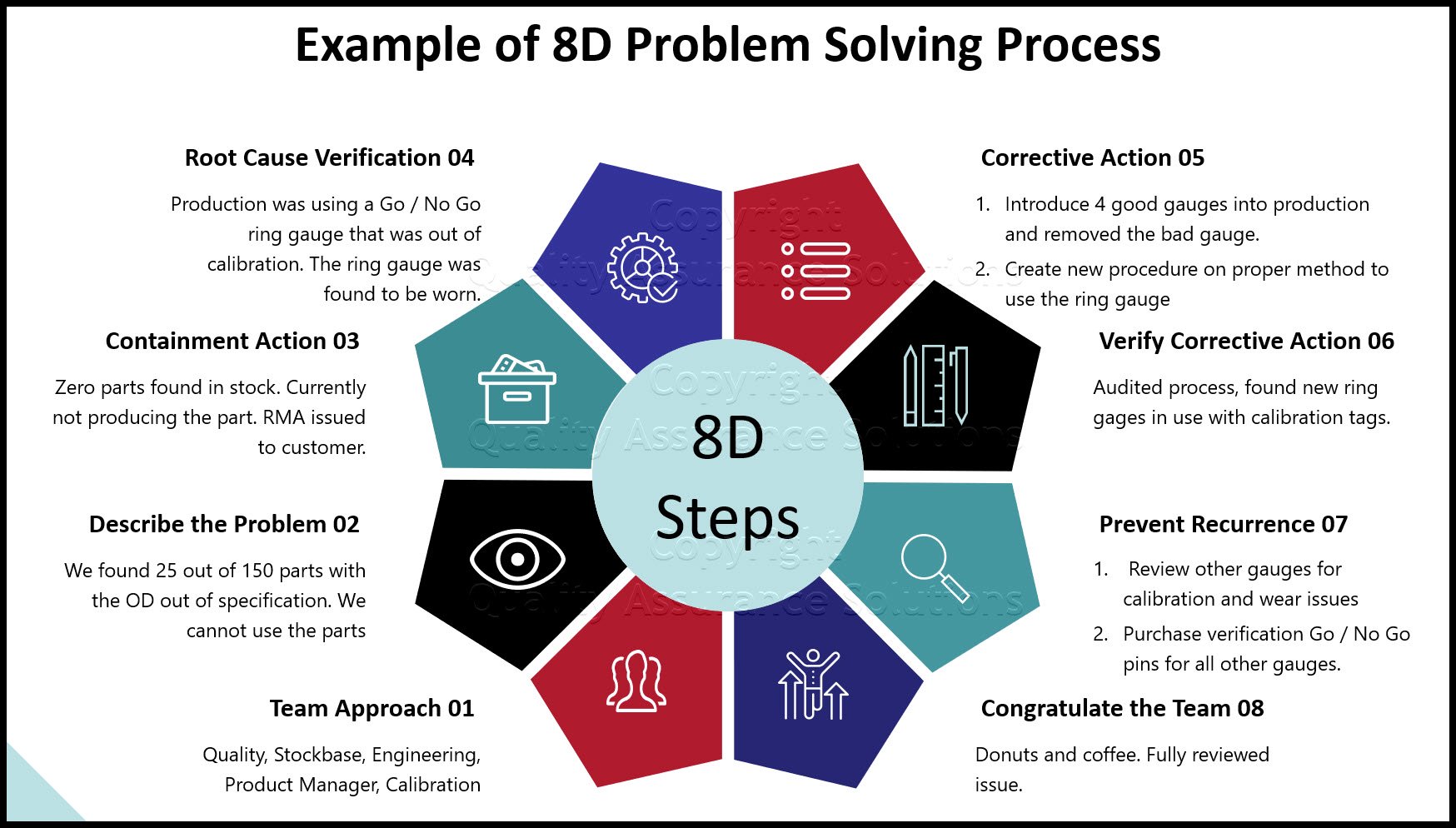

8D Eight Disciplines Example

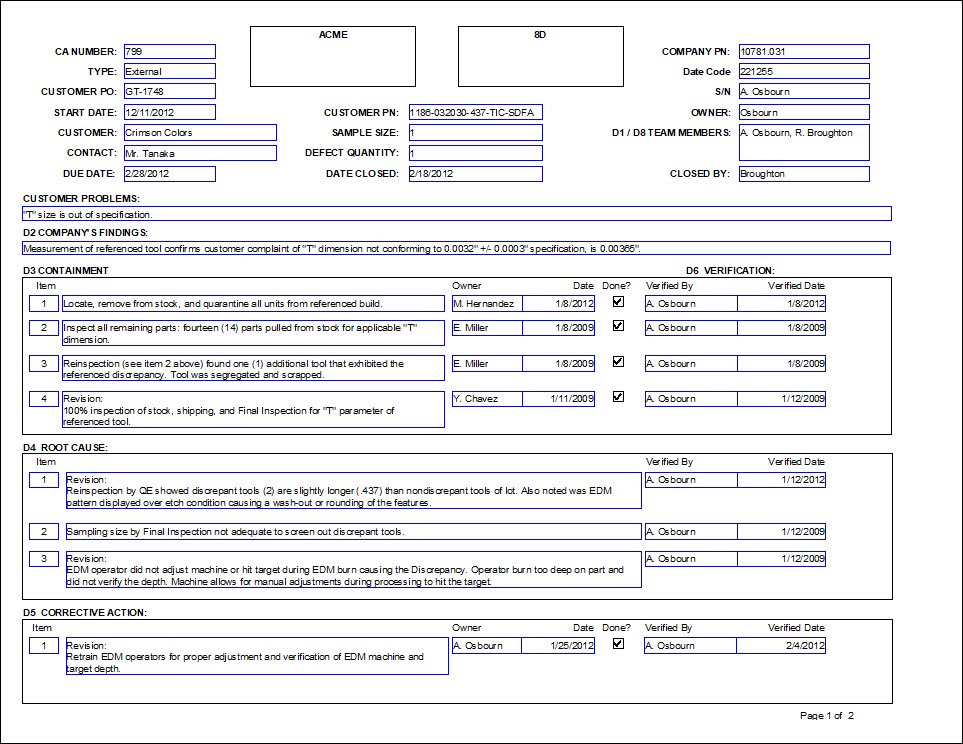

A popular Midwestern company that manufactures commercial heater delivers several hundred heaters to a trusted customer. The problem is that the customer's quality control team discovers defects in the varnish coating that are outside of the acceptable standards.

The company examined many different root cause possibilities. The engineering team identified the bathroom hand cream used by the employees as the root cause. This hand cream transferred from the employees hands to areas on the heater. This hand cream prevented the adhesion of the sprayed varnish. Therefore, the company asked employees not to use hand creams and removed the hand cream from the bathrrom. Below is an example of the 8D Eight Disciplines problem solving process approach.

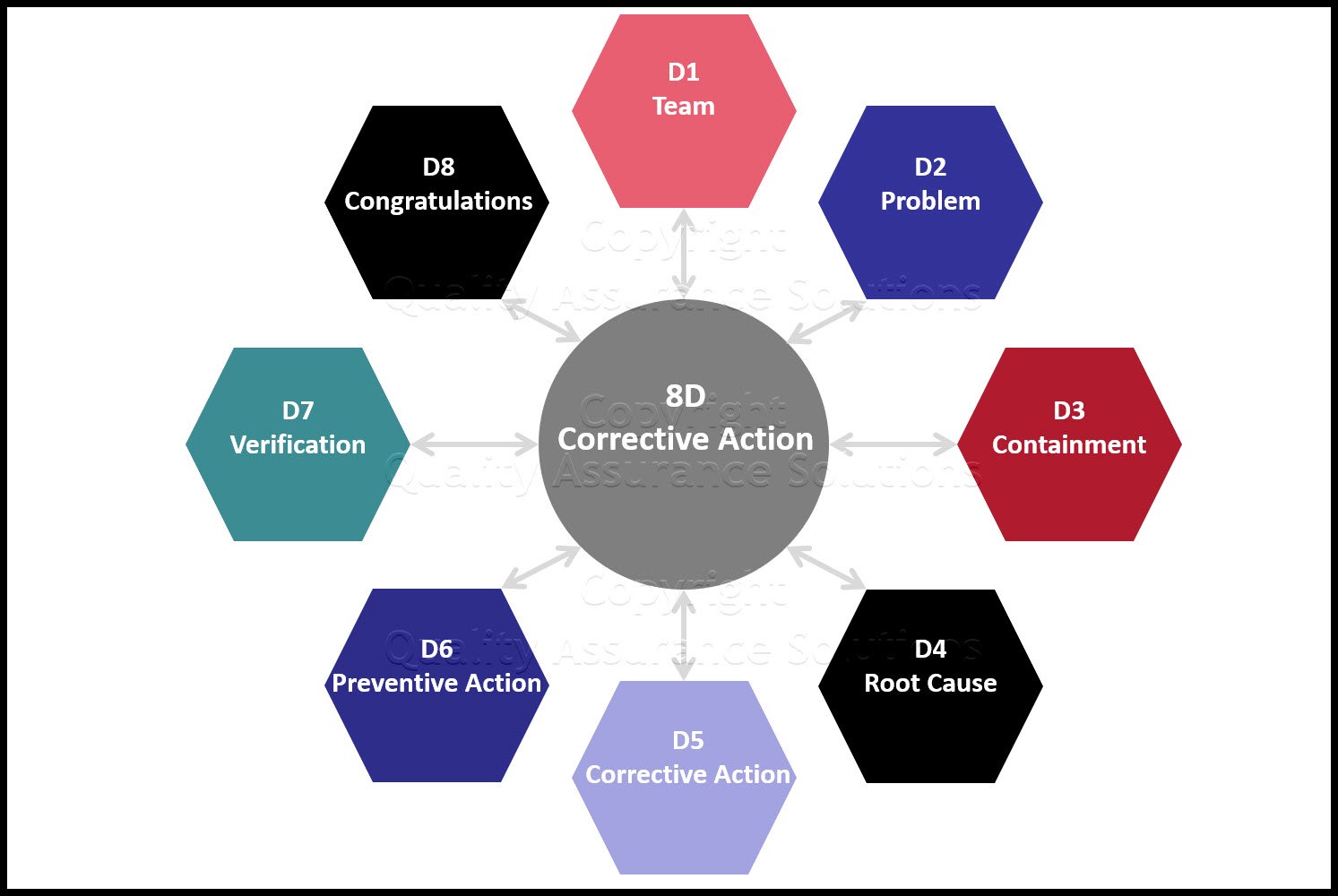

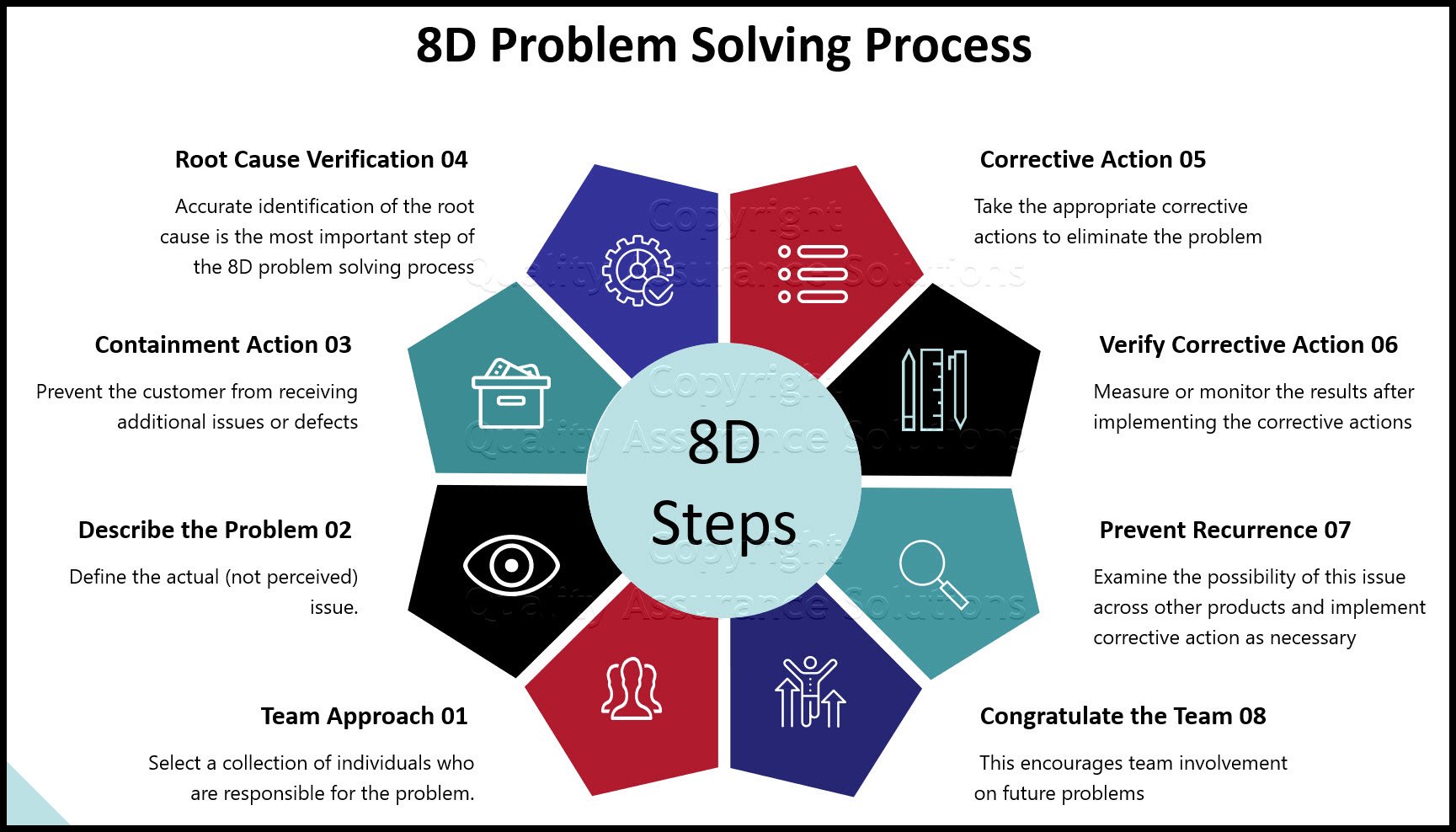

Step One: Team Approach

Assemble a Team. This included engineering, QA and the employees.

Step Two: Identify the Problem

Varnish defects in industrial heaters.

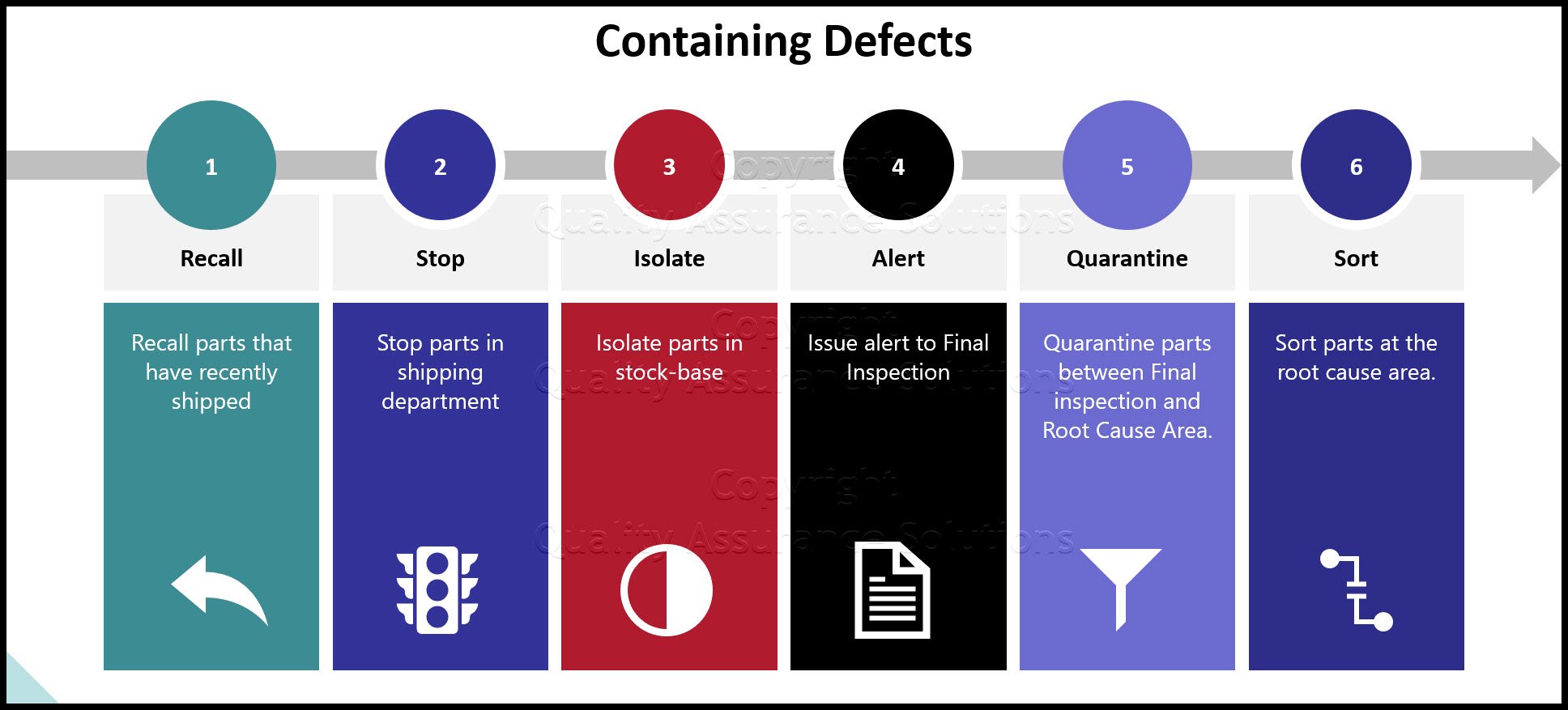

Step Three: Take containment action and measurements

The company reviewed its current inventories and the heaters at the customer. In addition it contacted other companies that bought the heaters with the sprayed tarnish.

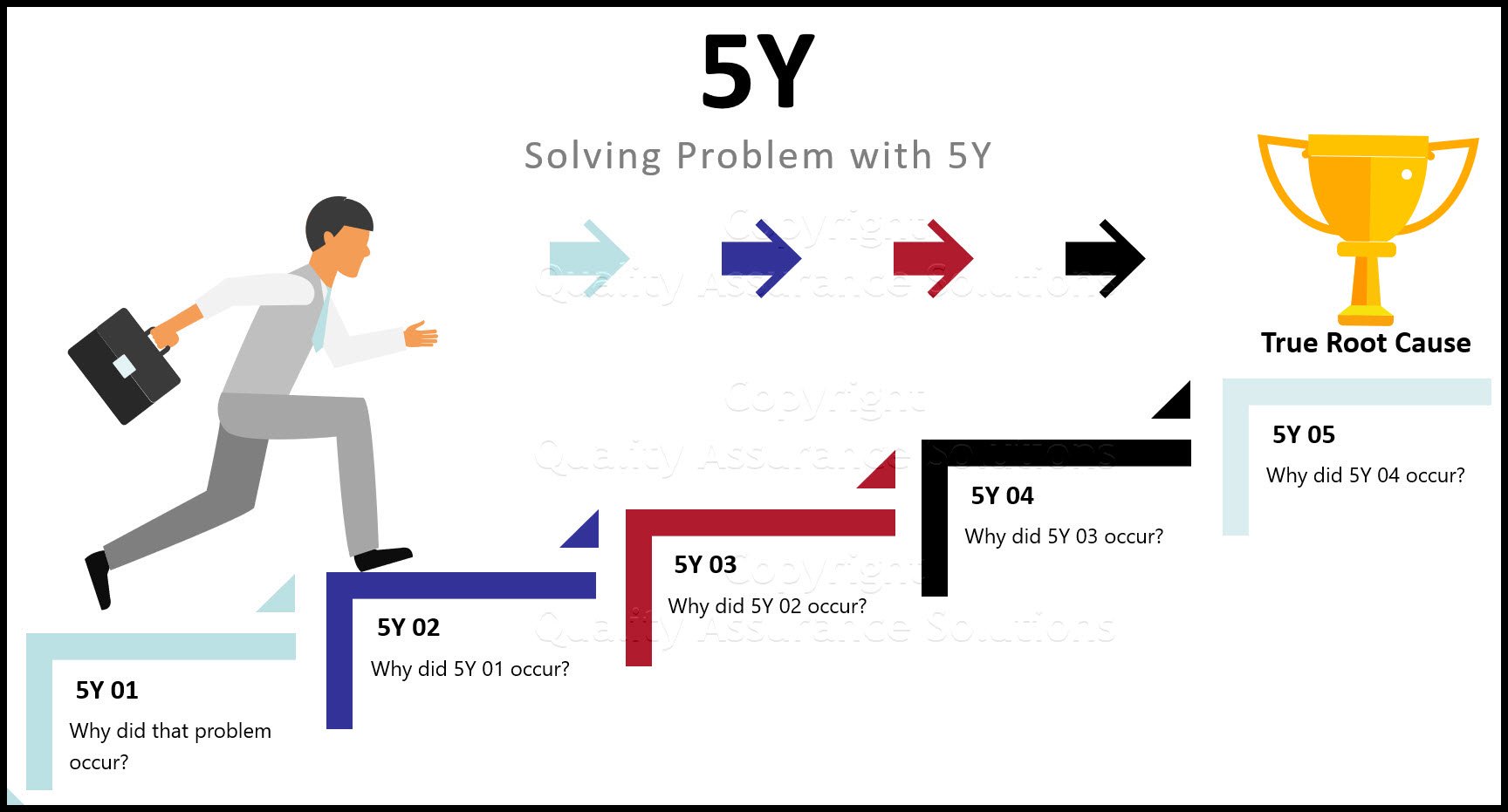

Step Four: Identify the Cause

Bathroom hand cream transferred from the employees hands to areas on the heater. This hand cream prevents the adhesion of the sprayed varnish.

Step Five: Take Corrective Action

1) Eliminate hand cream from all bathrooms

2) Disallowed purchasing to purchase this hand cream.

3) Insist employees do not bring their in their own hand cream.

4) Increase inspection to check for varnish issue.

Step Six: Monitor and verify the corrective action

QA conducted audits of bathrooms, raw materials goods.

Step Seven: Prevent Recurrence

1) Eliminate all hand creams

2) Post signs in restrooms not to use hand creams

3) Setup periodic audit to look for hand cream use.

Step Eight: Thank Team

After months of hard work, the team was congratulated because the situation had been resolved.

Conclusion

This 8D report was forwarded to the consumer, who understood the situation and thanked the company for resolving the problem in a timely manner.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

- QAS Home

- 8D Reports

- 8D Eight Disciplines

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |