Company Knowledge Management

Are you tasked with implementing Company Knowledge Management system, while

implementing all the requirements of the standard 9001:2015 into your

organization or business? As an ISO implementation consultant and certified auditor

for quality management systems, I know, that this can be a tricky thing. With sound planning and implementing your company systems, you can pass Third-Party audits

with no hick ups, no findings and no corrective actions.

WIKI vs Company Knowledge Management

One thing upfront…establishing a short WIKI is not knowledge

management and does not cut it with ISO 9001:2015. Instead, I recommend a sure-fire method. It might not be the only way, but I passed several ISO

9001:2015 Third Party CB audits within several industries with these implementation strategies and with

zero findings.

First, you should develop as a baseline a SOP (Standard Operating Procedure) for Management of Knowledge in your organization. To do this, I usually clarify with the company top management, how they currently capture knowledge in the company. I then audit them on whether this might be enough to satisfy the new ISO requirements. But again, to develop a WIKI alone does not cut it here.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

What are the differences between company knowledge management system as a strategy and a technology-only WIKI approach?

Lets look at definition of knowledge management (KM): KM enables the organization to achieve objectives better and faster through an integrated set of initiatives, systems and behavioral interventions. It promotes smooth flow and sharing of knowledge relevant to the organization and eliminates reinvention. KM facilitates the flow of knowledge from its' origin to its' use which then achieves the organization’s objectives.

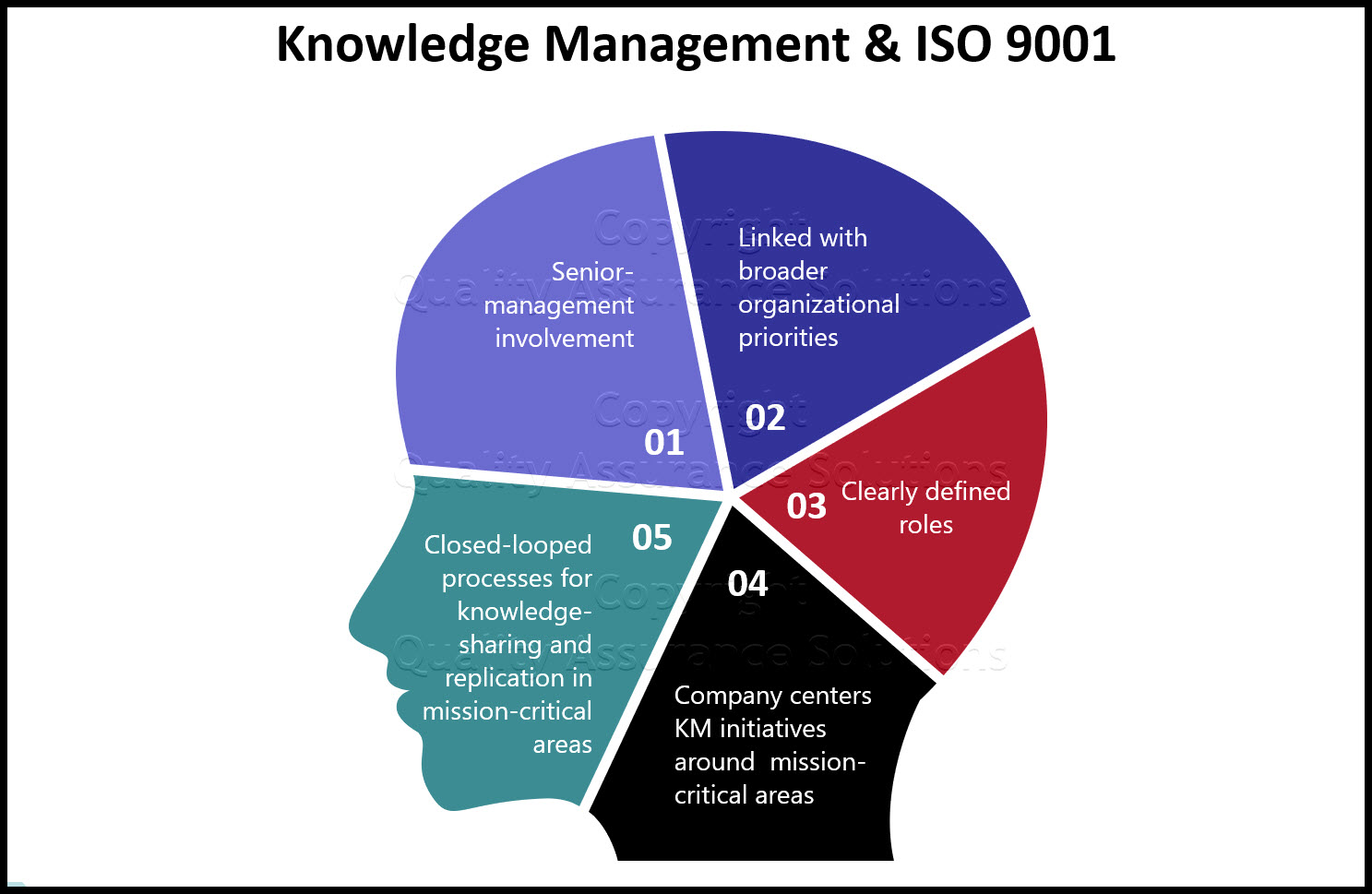

A great strategic Company Knowledge Management Program includes the following:

- Senior-management involvement

- Linked with broader organizational priorities

- Company centers KM initiatives (such as knowledge-bases, communities of experts, and collaboration) around predefined “mission-critical” areas

- Clearly defined KM roles.

- Closed-looped processes for knowledge-sharing and replication in mission-critical areas—not left to choice or chance.

So here we have it…technology is an important enabler, but clearly only one component of a great KM program.

Some key questions that may come up during an audit.

- Does the company owner maintain a succession plan?

- Does your company capture the knowledge of retiring key managers?

- Can new key hires quickly access the knowledge and utilize it in day to day activities?

Standard Operating Procedure

Flesh out the Company Knowledge Management SOP to meet the above requirements. Make sure it becomes part of the change and knowledge management culture in the organization. Discuss KM as a line item in your QMS management review. This assures top management sees its' effectiveness, whether it needs changes, and whether it needs new action plans to improve Knowledge Management.

I normally upload E.W. Deming’s 14 point strategies as principles into the KM concept. I discuss it in training sessions with top management. This reminds them of the necessity of quality and knowledge management.

This SOP approach also pleases the Certifying Body auditor. They look very carefully for all the new requirements of the 2015 version. They review the new requirements and your SOP(s) covering it. Company Knowledge Management system becomes a vital part of the entire QMS.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

DOD vs ISO 9001:2015

Even advance organizations like the US Department of Defense do not utilize KM on a sophisticated ISO 9001:2015 level. Lets take an examination of the Lesson Learned system within the US DOD.

I was assigned to a multi-million-dollar transnational

Department of Defense project years ago. I experienced firsthand, how

MIL/GOV environments managed Lesson Learned within ISO 9001 Quality Management Systems.

Recognizing the need to quickly react in the event of combat, the DOD developed a lesson learned collection process. This process allowed the military to collect lessons from anywhere. The military executes a combat mission for analyzing field data, and disseminating, integrating, and archiving lessons from operations and training.

In summary the DOD Lesson learned system consists of these components:

- Plan

- Collect

- Analyze

- Publish

- Distribute

- Archive.

Exercising each of these components in a systematic process resulted in lessons learned and information that usually provided an intelligent approach to operations.

However, U.S. Department of Defense DOD suppliers used quality assurance methods and lessons learned from mostly PRODUCT examination only. Although the DOD extensively used knowledge management extensively, their method did not meet the ISO 9001:2015 requirements.

In the DOD product development centric projects, they utilize ISO 9001 QMS around zero defect product development. But often this does not include capturing knowledge management and other ISO 9001 capabilities, like tracking/managing nonconformities and tracking organizational “soft” process interruptions.

Even when conducting six sigma projects, very often, lesson learned only influenced product development improvements. These projects do not positively influence the ENTIRE organization like ISO 9001:2015 does.

ISO 9001:2015 is much broader and more prescriptive in managing organizational processes and its' interruptions. The new ISO 9001:2015 structured focuses on high effectivity, with clear inputs, activities and outputs / KPI. It promotes a structured problem solving Corrective Action / Risk Preventive Action System for ALL QMS processes, not only product related processes. What a great advantage to have!

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Working with Knowledge Management

The DOD Plan, Collect, Analyze, Publish, Distribute and Archive structure can influence ISO 9001 based knowledge management clause and can be included into your official QMS SOP’s for Company Knowledge Management system. But Lesson learned influences a QMS based on ISO 9001:2015 MUCH MORE EFFECTIVELY in three ways…

- Lesson Learned influences and improves changes of the entire QMS processes and procedures. By sharing updates and changes this creates new implementation of tactics, techniques and procedures to transform all lessons learned into knowledge.

- Within the context of ISO 9001:2015 based QMS, Lesson learned results must be also seen as PROCESS INTERRUPTIONS, which must be registered within QMS NONCONFORMITY LOGS / REGISTERS as nonconformities! Then a decision must be made, correction (To fix the problem) or Corrective Action needed (To really SOLVE the problem for good), which therefore mostly needs…

-

The need for an official Six Sigma Project. The resulting outcome stays stays traced in a closed loop system until resolution of the problem. This then becomes a lesson learned.

However, as a caveat, these six sigma projects are product related. Unfortunately, most available “quality experts” are product quality experts and not a knowledge / complex process change manager. In addition, product team members come from engineering, and not from change / continuity / and Business Risk Management. Therefore, these six sigma projects very often don’t get managed effectively in ISO 9001:2015 eyes.

In my findings, third-party and internal auditors don’t audit these projects well because they are also product specialists too. They are not familiar with auditing change management. Unfortunately their audits provide low improvement results in overall organizational change based on lessons learned!

Closed Loop System

Lesson learned, articles, and information from all of the organization enables others to learn and refine training. But organizational improvement potential based on ISO 9001:2015 QMS is still not leveraged 100%.

Therefore, we must use the in ISO 9001:2015 available nonconformity tracking with an established closed loop system. To fully makes company knowledge management effective, you must include VERIFICATION OF THE BEHAVIORAL CHANGE within the closed loop. Without this, your lesson learned system falls short very often!

Support your organization by implementing these changes in lesson learned management as early as possible! Like in product development, where we find that problem avoidance must be executed as early as possible during the product planning phase, the same applies here!

New behavioral change in company knowledge management, influences the organizations’ ISO 9001 QMS and spreads throughout the organization. This influences training and afterwards prevents daily business problems.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Implementing Knowledge Management

If all this makes some sense to you, I recommend that you look out for more education and company knowledge management with our ISO 9001:2015 Implementation Kit. It includes a STANDARD OPERATING PROCEDURE for Knowledge Management and complies to ISO 9001:2015.

With new business management methods and tools like ISO 9001:2015 which now includes company knowledge management requirements, you can influence your internal lesson learned system in a very positive way. To leverage this, you must bring KM and lesson learned into value stream routing. This includes input from task-organized teams and subject matter experts, who should contribute on a regular basis.

As general guideline, focus on the new clause 7.1.6 in ISO 9001:2015, where it describes the requirements for the handling of organizational knowledge in the following four phases. Analogous to the PDCA cycle...

- Determine the knowledge necessary for the operation of processes and for achieving conformity of products and services.

- Maintain knowledge and make it available to the extent necessary.

- Consider the current organizational knowledge and compare it to changing needs and trends.

- Acquire the necessary additional knowledge.

Let me finish with a joke I heard some years ago, which reflects the equation of knowledge versus wisdom…

One Sufi tale goes like this: A father and son stand together looking up at the night sky and the father says, "Son, I am concerned that you are seeing double." The son smiles up at his father and responds, "Father, how can that be? If I were seeing double there would be four moons instead of two." This story conveys wisdom.

Article written by Robert Jasper of Art of Quality for Quality Assurance Solutions. Article edited and posted by Quality Assurance Solutions

- QAS Home

- Knowledge Management

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |