Cost Of Quality

When it comes to making decisions, most managers speak money. The Cost Of Quality theory provides the vocabulary to communicate between quality professionals and their managers.

The Meaning Of "Quality Costs "

The term quality costs means different things to different people. Some equate quality costs with the costs of poor quality due to finding and correcting defective work. Others equate the term with the costs to attain good quality. Others use the term to mean the costs of running the quality department. In this site, the term "quality costs" means the cost of poor quality.

Normally, quality-related costs run in the range of 10 to 30 percent of sales or 25 to 40 percent of operating expenses. They can both be visible and hidden. The cost of quality not only includes factory operation, but the support operations significantly contribute too.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Most companies can avoid quality costs. However, these companies do not assign clear responsibility for action to reduce them. Nor do they create a structured approach for doing so.

Tips You Must Know:

The language of money is essential. Without quality cost figures, it makes communicating poor-quality information to upper management slow and ineffective.

Quality cost measurement (only) does not solve quality problems. Some organizations publish it in the form of a scoreboard, but these efforts fail because of lack of action.

Don't limit the scope of quality costs. Most people focus their quality cost efforts only on the cost of nonconformities. Quality costs include other unmeasured costs such as lost sales due to poor quality. We call this a hidden cost because we cannot easily measure it.

Categories Of Cost Of Quality

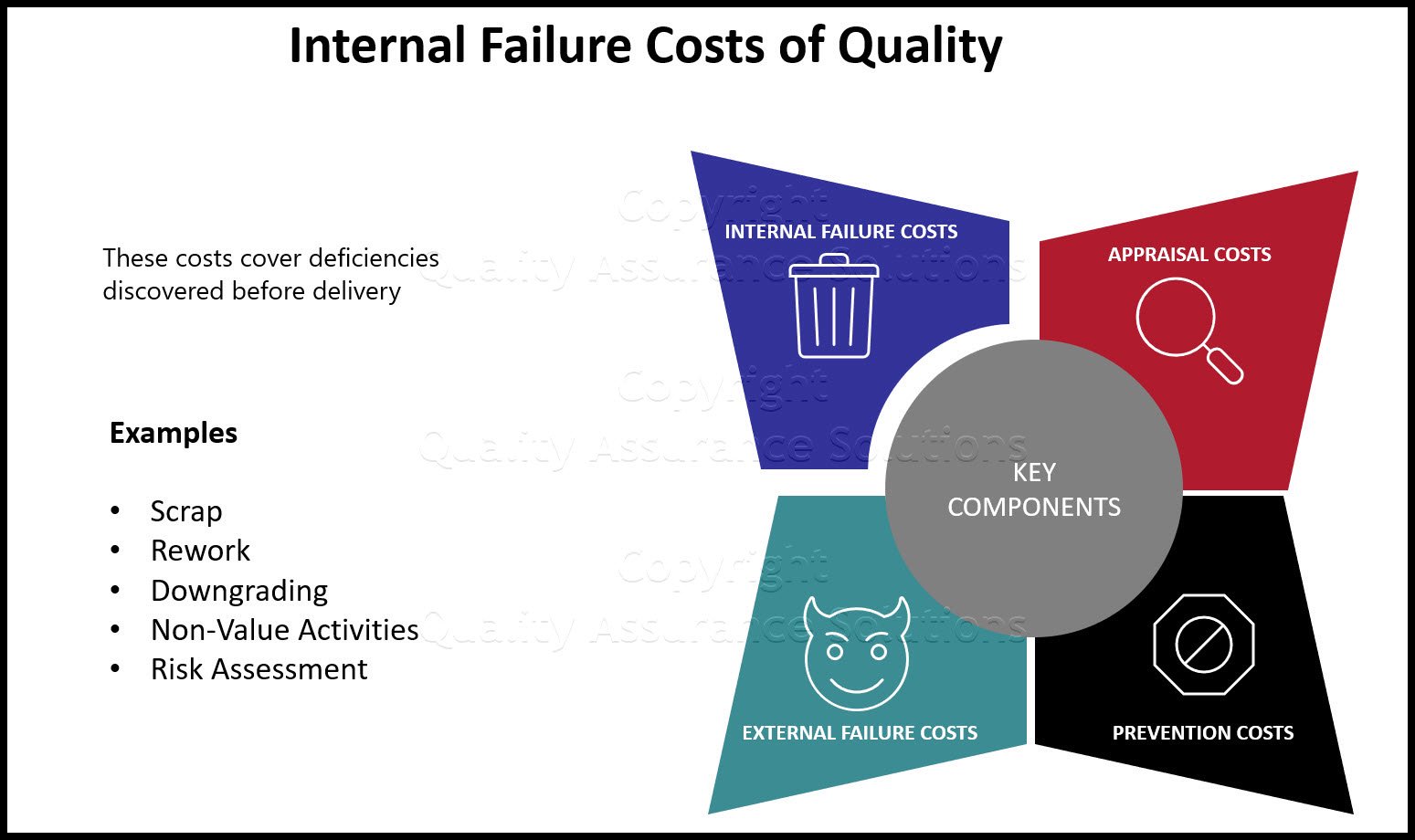

1-Internal Failure Costs

These costs cover deficiencies discovered before delivery. We associate deficiencies or nonconformities with the failure to meet explicit requirements or implicit needs of external or internal customers.

Learn more on Internal Failure Costs

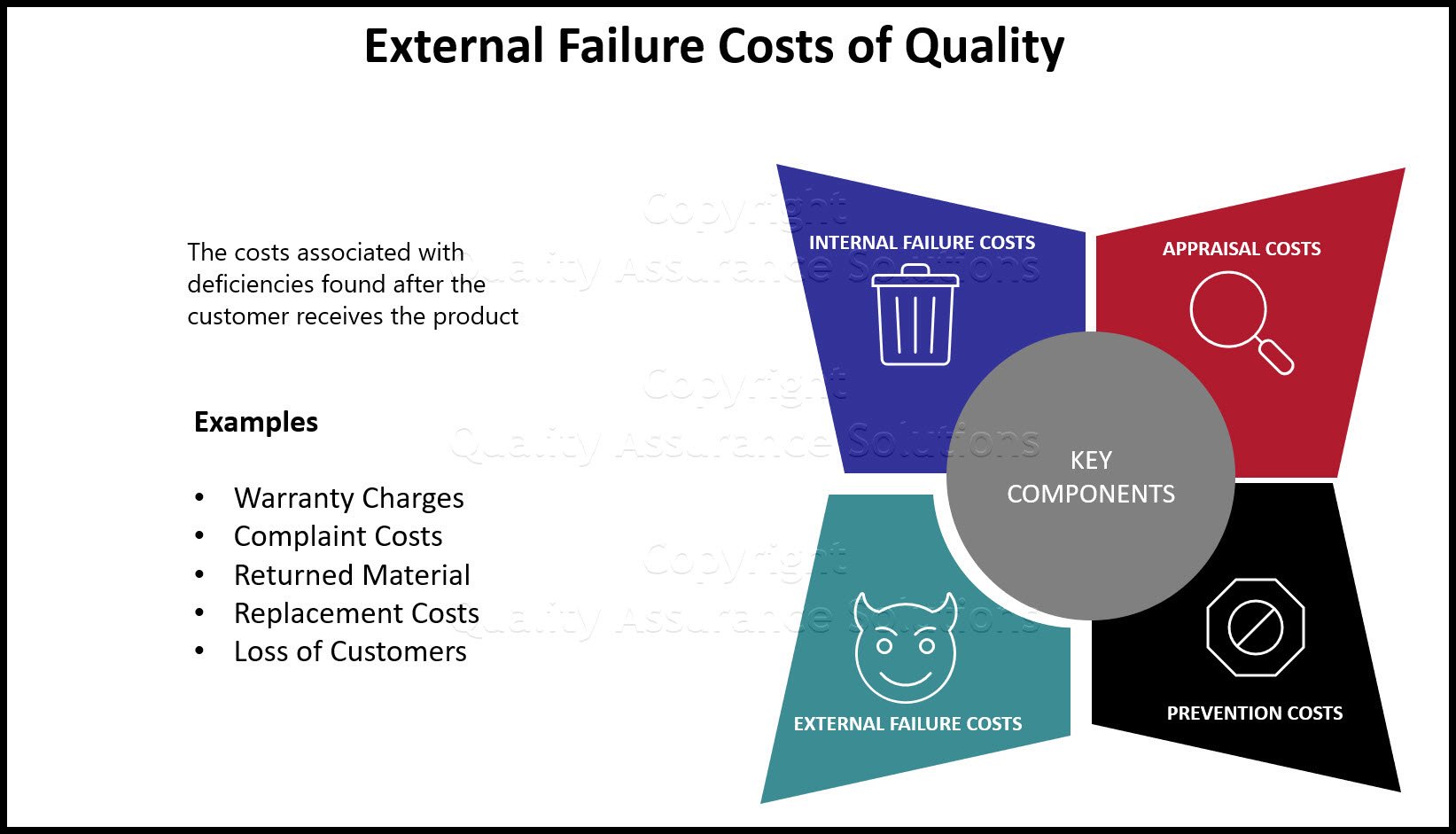

2-External Failure Costs

The costs associated with deficiencies found after the customer receives the product. These also include lost opportunities for sales revenue.

Learn more on External Failure Costs

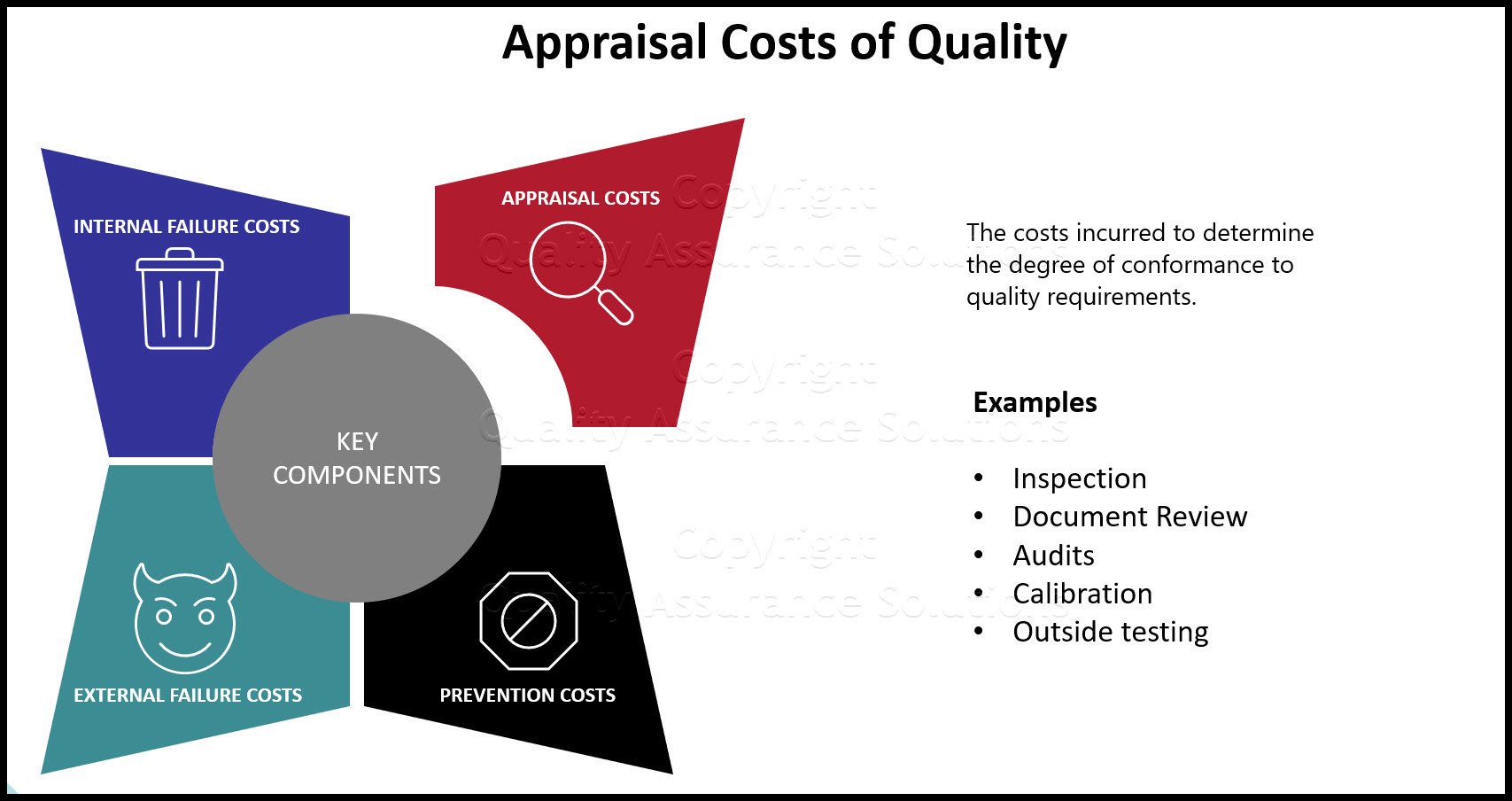

3-Appraisal Costs

The costs incurred to determine the degree of conformance to quality requirements. For example, inspection cost is an appraisal cost.

Learn more on Appraisal Costs

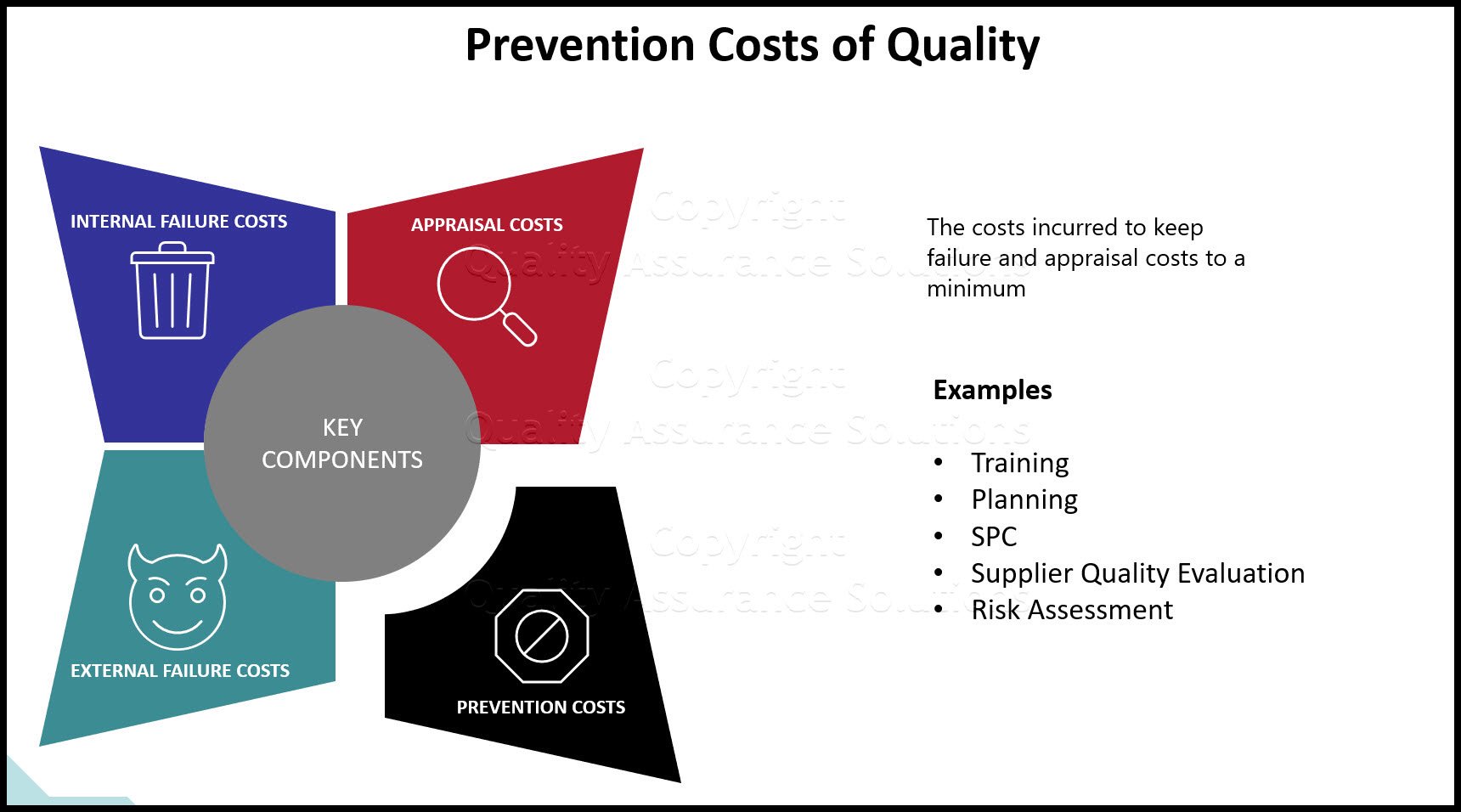

4-Prevention Costs

The costs incurred to keep failure and appraisal costs to a minimum. For example, product design or Poke Yoke costs are prevention costs.

Learn more on Prevention Costs.

The total cost of quality is the sum of the four above categories.

Get certified in Risk Management through our completely on-line training system. Study at your own pace.

Creating an Initial Quality Cost Study

1. Review the literature on quality costs. Consult with others in similar industries who have had experience with applying quality cost concepts.

2. Select one organizational unit of the company to serve as a pilot site. This unit may be one plant, one large department, one product line, etc.

3. Discuss the objectives of the study with the key people in the organization, particularly those in the accounting function. Two objectives are paramount...Determine the size of the quality problem and identify specific projects for improvement.

4. Collect the convenient accounting system cost data. Use this information to gain management support to make a full cost of quality study.

5. The proposal should provide for a task force of all concerned parties. The task force identifies the work activities that contribute to the cost of poor quality. Use work records, job descriptions, flowcharts, interviews, and brainstorming to identify these activities.

6. Publish a draft of the categories which defines the cost of quality. Secure comments and revise.

7. Finalize the definitions and secure management approval.

8. Assign responsibility for data collection and report preparation.

9. Collect and summarize the data. Ideally, this should be done by accounting.

10. Present the initial and final quality cost results from the quality improvement project to management. Request authorization to proceed with a broader company-wide program of measuring the costs and pursuing projects.

Clearly, the sequence must be tailored for each organization.

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

Capturing Quality Cost Tips

1. Established expense accounts. Examples include inspection department appraisal activities and customer response warranty expenses.

2. Define an analysis for the ingredients of established expense accounts: For example, suppose an account called customer returns reports the cost of all goods returned. Some customers returned defective goods. Categorized these as cost of poor quality. Some customers return goods to reduce inventory. These are not costs of poor quality. You must break the customer returns into two separate expense accounts. To help distinguish the quality costs returns, someone must study the return documents and classify all returns.

3. Improve accounting documents: For example, some production department employees conduct product inspection. By securing their names, the associated payroll data, and inspection time you can quantify these costs of quality.

4. Include estimates: Input from knowledgeable personnel is clearly important.

5. Use temporary records. For example, some production workers spend part of their time repairing defective product. Here you can create a temporary record to determine the repair time and thereby the repair cost. This cost can then be projected for the study time period.

6. Utilize work sampling: Take random observations of activities. With a few sampling, you can calculate the percent of time spent in predefined quality cost categories. Ask employees to record the observation as prevention, appraisal, failure, or first time work.

7. Improve allocation of total resources: For example, some engineers are part-time engaged in making product failure analyses. The engineering department, however, makes no provision for charging engineering time to multiple accounts. Ask each engineer to make an estimate of time spent on product failure analysis. Do this by keeping a temporary engineering activity log for several representative weeks. Categorized time spent due to a product failure as a failure cost.

- Track unit cost data: Here, the cost of correcting one error is estimated and multiplied by the number of errors per year. Examples include billing errors and scrap. Note that the unit cost per error may consist of corrections costs from several departments.

- Utilize market research data: Cost of quality includes lost sales revenue due to poor quality. Although difficult to estimate, market research studies on customer satisfaction and loyalty can provide input data on dissatisfied customers and customer defections.

8. Consider using 8D Manager, corrective and preventive action software, which lets you assign quality costs for each taken action when the company encounters quality issues. The software automatically calculates the costs and creates charts for these costs.

What Do You Know About Cost of Quality?

Do you have experience (good or bad) with COQ? Or A question about COQ? If it is a question, please let us know your answer / thoughts too.

Other Visitors COQ Comments

Click the below links to see the comments and to reply.

Trapping Quality Costs

How does a company trap the quality cost category that the accounting system of the company don't have access to?

QAS Home > Cost of Quality …

How to Treat the Operating Cost of Customer Service center in the perspective of cost of quality?

IT company has the organization and infra for customer service. We call that customer service center. (Ex. Call center)

To operate the service center, …

Standard Category for Hidden Quality Cost and Corresponding Measurement System?

Hidden quality cost has been researched by many researchers in recent years. There is little standard classification for invisible quality loss cost due …

There are Four Specific Types of Quality Costs

The four particular sorts of quality expenses are

Prevention costs

Appraisal costs

Failure costs

Internal failure costs

External failure costs …

The expenses incurred for training?

a)appraisal cost

b)internal failure cost

c)prevention cos

d)Loss of opportunities

QAS Home > Cost of Quality > Training Expenses …

Quality Costs versus Quality Gains (Revenues)

Why shouldn't we use quality Gains or(Quality Added Revenues) instead of such a confusing Quality Cost?

In my opinion, any Quality project should …

how to calculate quality cost

how to calculate quality cost. what are the factors to consider if your company is a service company that is heavy on manpower and client servicing.

…

I want a systematic software for capturing and calculating COQ Not rated yet

You have very well explained about COQ.

I am a COQ Practitioner

How best to convince top managemnt that there is cost incurred for poor quality, quantifying it Not rated yet

Allow QM people view management accounts

Explore where most spending goes

Determine if there is Pareto use of funds and time or effort in those

Check …

Reducing Quality Costs Not rated yet

Our solution (for many years now) is to let money speak. We are in a B2B2C market of partially man made, produced to order products with a high rate of …

Internal Costs Not rated yet

I have seen a feature article in Quality Progress where an organization took credit for a multitude of cost and other savings. But at the expense of other …

- QAS Home

- Cost of Quality

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |