Conforming vs Nonconforming Material Control System

Conforming vs Nonconforming Goods

Conforming means the material meets the requirements.

Nonconforming means the material does not meet the requirements.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Nonconforming Material Control System

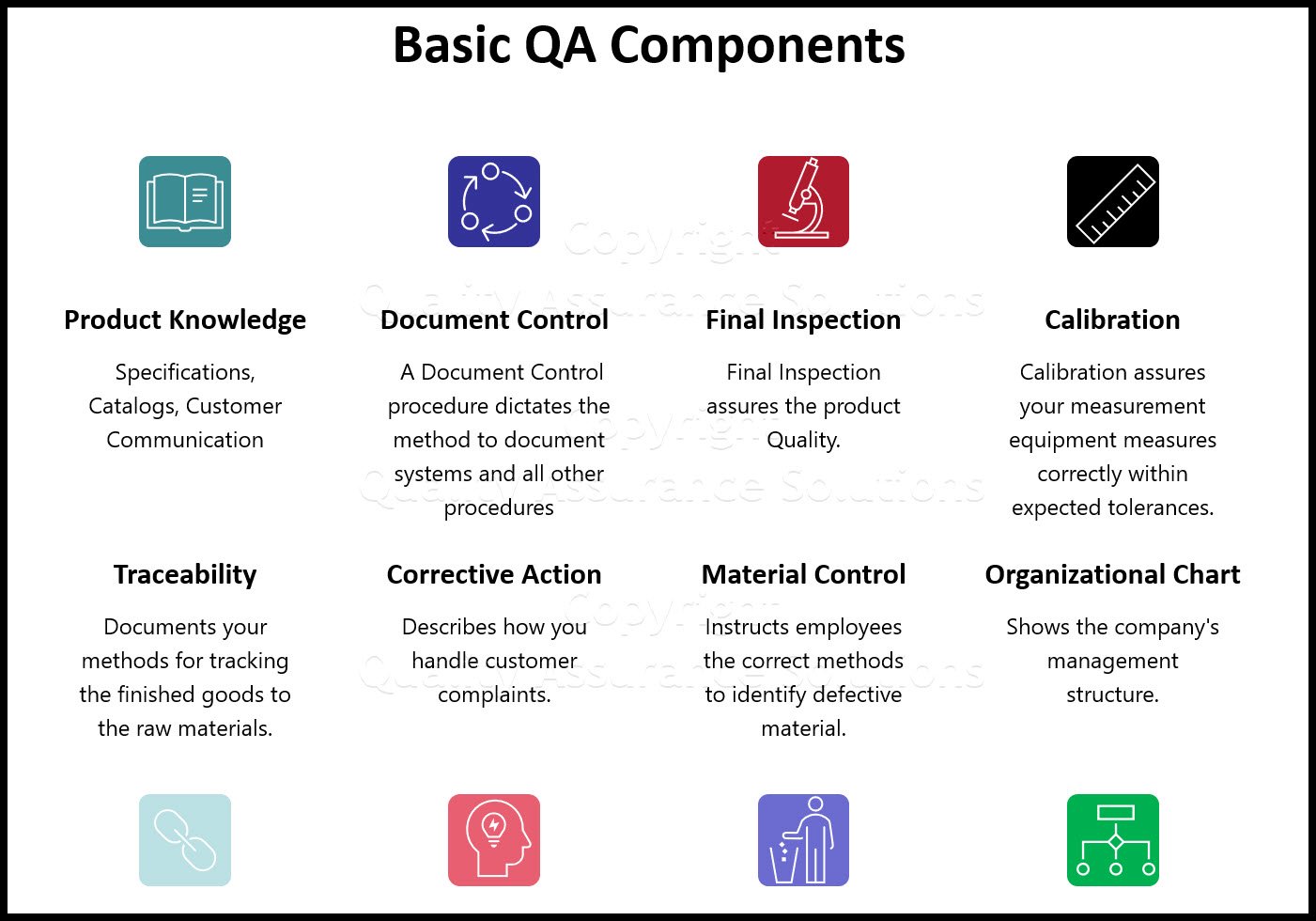

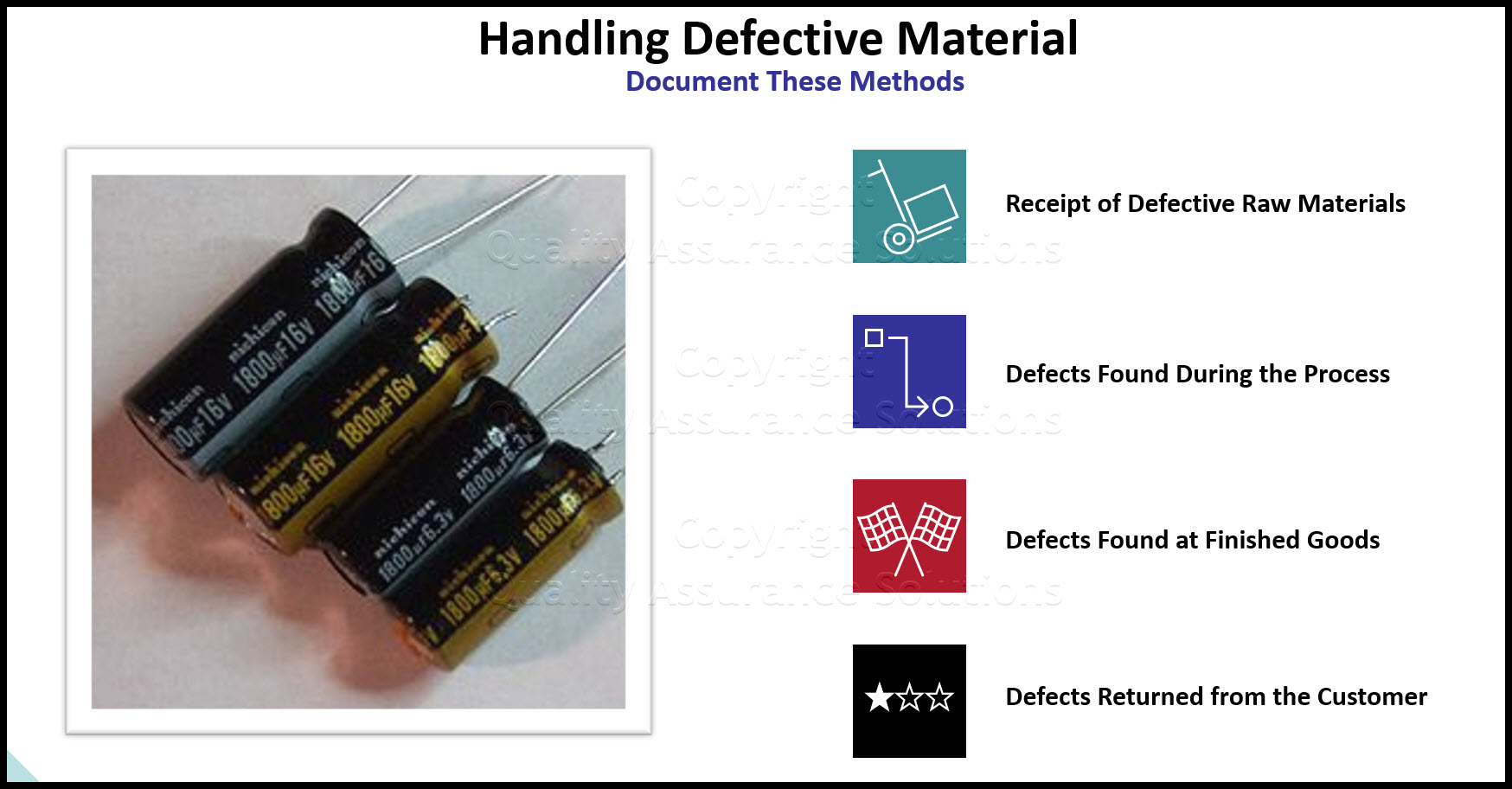

You must have a system that directs your nonconforming material control. Every Quality Assurance program addresses this issue. This system prevents defective material from being processed, consumed, or shipped. When documenting this system consider these processes:

- Receiving Inspection

- Process Defects

- Product Defects

- Finished Goods Containment

- Returned Material

- In process product specific containment

Within the documented system include the method for identifying the nonconforming item. Discuss when the nonconformity is introduced into your problem solving corrective action system. Cover the disposition possibilities which could include: scrapped, reworked, regraded, sorted, and acceptable with QA approval.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

Labeling and Segregating

For receiving inspection cover how conforming and nonconforming material is controlled. Label and segregate the defective material away from the conforming material. We recommend a hold cage or a secured area for the nonconforming material.

Document your methods for handling process defects which includes machines that are not performing to the requirements. You can tag out / lock out these machines or label with a “Do Not Operate Sign” until the machine is fixed.

Product defects, finished nonconforming goods, and returned nonconforming material need to be labeled as nonconforming and segregated away from the conforming material. Ideas for this include:

- Place the material in a hold cage

- Place the material in a labeled scrap bin

- Put locks on the product so it cannot be used.

- Remove it from the production floor

- Recycle it

- Place it in a labeled lock cabinet

Nonconforming product created during the process stages may need different identification and segregation methods than defective finish product. If applicable document these methods in the nonconforming material control system.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Documentation Method

We recommend having one document that covers conforming vs nonconforming materials. However, it is ok to cover nonconforming material in localized procedures. For example a receiving inspection procedure could cover how to handle nonconforming material. Include labeling, segregating and disposition criteria for each procedure. If you go with localized procedures, make sure you can identify those procedures for the processes listed above.

Employee identification of Conforming vs Nonconforming product is vital, making nonconforming material control a basic QA system. It assures defective material is not used by your employees. It assures your customers do not receive defective product. Since it is a fundamental system, train all appropriate employees.

- QAS Home

- Material Control

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |