Quality Management

Control Plan

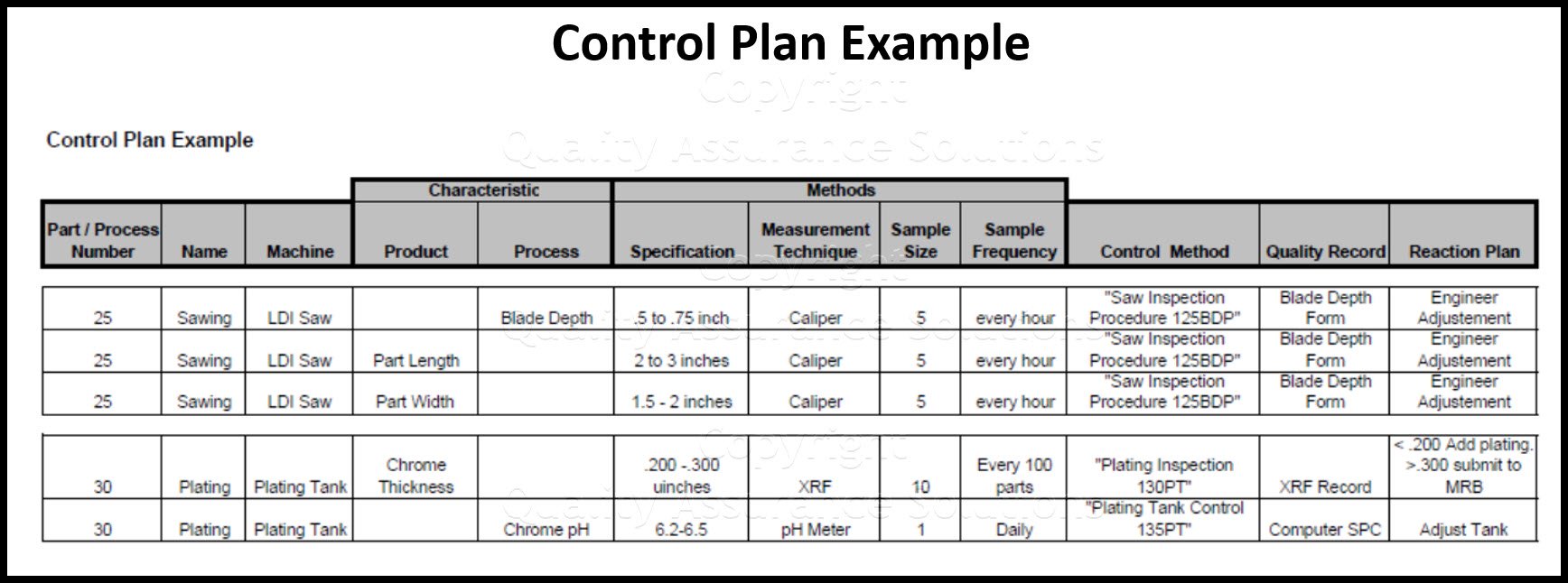

A Quality Management Control Plan is an easy to read summary of your process inspection points. Please sign up for our E-zine to download an example of the control plan. This is a nice document to present to your customers when they want to understand your production processes. The control plan presents your company's methods on monitoring and measuring the process and product conformity.

It is also useful for internal audits. The auditor can take this document and use this for the starting point of a process audit.

It is a great reference tool when you need to review your process during a corrective action activity.

The control plan is valuable for training new employees. They can easily grasp the process flow, inspection points, specifications, and process documentation all from one document.

Snap Sampling Plans! software combines all the key industry standard attribute sampling plans into one place.

With over 10,000 sampling possibilities, Snap Sampling Plans! guides you in selecting the correct AQL sampling plan.

ISO 9001

For ISO 9001 registration, the control plan is not mandatory, but highly recommended!. The Control Plan will impress your auditor. It shows that you have thought out your inspection steps and you understand the big picture with regards to product quality. It supports these elements of the ISO 9001 standard.

- Monitoring and Measuring of the Product

- Monitoring and Measuring of the Process

- If done correctly, it can support Design and Development Planning

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Quality Management Control Plan Elements

Part / Process Number – This is your company internal number for the part or process. It could be a department number, process flow number, a part number or whatever you deem appropriate.

Name – This is the name of the part or process.

Characteristic – Name the characteristic that is being measured. If it is a direct measurement of the product list under the product category. If you are measuring the process, list that characteristic in the process column.

Specification – Record the specification for that characteristic.

Measurement Technique – Name the measuring instrument. Make sure the instrument is calibrated.

Sample Size – the number of parts that you are measuring

Sampling Frequency – how often you are conducting the measurement

Control Method – the procedure that states how to conduct the measurement.

Quality Record – State how the measurements are recorded. This could be a specific handwritten form, computer spreadsheet or an SPC program.

Reaction Plan – State what is done if the measurement does not meet the specification.

- QAS Home

- Control Plan

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |