Takt Time

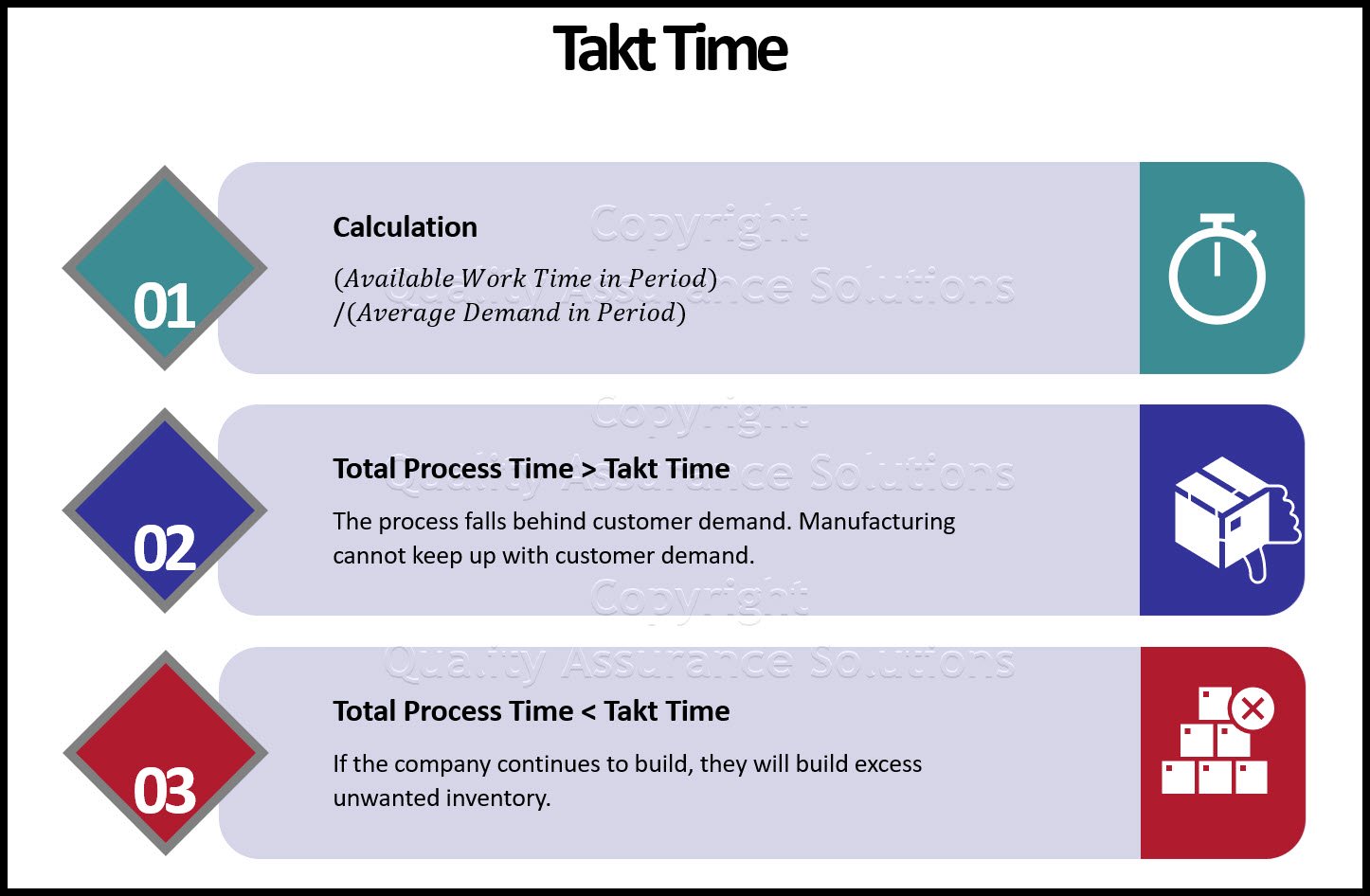

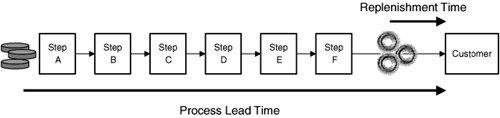

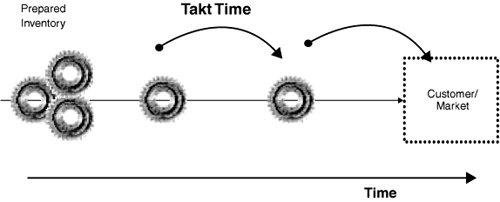

Takt Time is defined as "The rate at which the end product or service must be produced and delivered in order to satisfy a defined customer demand within a given period of time. It is calculated as:

For example, if a process runs 24 hours a day and the market demand is 240 entities per day then:

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

Cycle Time And Takt Time

In lean sigma terms, your processing time to produce an item is known as the global process cycle time. Thus, if the global process cycle time is above the takt cycle time, the process falls behind customer demand. If the global process cycle time is less than the takt cycle time then you build excess inventory.

If the takt was five minutes in the above example, then the process is cycles faster than customer demand and builds inventory. To prevent this the company needs to wait one minute in every six wait.

If the work period is less than 24 hours per day, then the process has to go proportionately faster to meet the daily market demand. For example, if the work period is 12 hours per day in the preceding example, then the new takt time is now three minutes. The process must cycle twice as fast. If the global process cycle time is not three minutes, the process does not balanced with the demand.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Multiple Products

Most processes deal with more than one product. Adjust takt cycle time to take this into account.

For example, if a process has two main products:

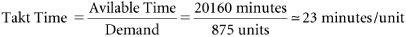

- Product "A" currently has demand for 350 a month

- Product "B" currently has demand for 525 a month

Then the total demand is 875/month.

If the business runs a two-shift operation, 5 days/week, 4.2 weeks/month

- 5 days x 4.2 weeks = 21 available days

- 21 days x 16 hours = 336 hours

And so monthly available time is 336 hours x 60 minutes = 20160 minutes

Calculating Takt Cycle Time:

Step 1. Identify the Takt process(es). Takt is process-specific and should not be aggregated across multiple lines unless they generate the same entity types.

Step 2. Select the time period, usually a week or a month. Identify the true time available to produce units within that period.

Use minutes for the unit. If using monthly demand, then the time available per month is

(#Days/Month x #Shifts/Day x #Hours/Shift x #Min/Hour)

If using Weekly demand, then the time available per week is

(#Shifts x #Days/Week x #Hours/Shift x #Min/Hour)

The available work time should be calculated based on the full-shift time. Because the below elements exists, don't deducted the following:

- Wait for information or material time

- Rework time

- Equipment breakdown time

- Regular labor break time

- Fatigue/rest time

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Step 3. Identify the entities that flows through the process during the next time period.

Step 4. Calculate the total demand for this process for all of the entities identified in Step 3. This is a count of entities. As in the preceding example, if the demand is for 350 units of Product A and 525 units of Product B, then the total demand is 875 units.

Step 5. Calculate the Takt Time from the work time calculated in Step 2 and the demand calculated in Step 4 as

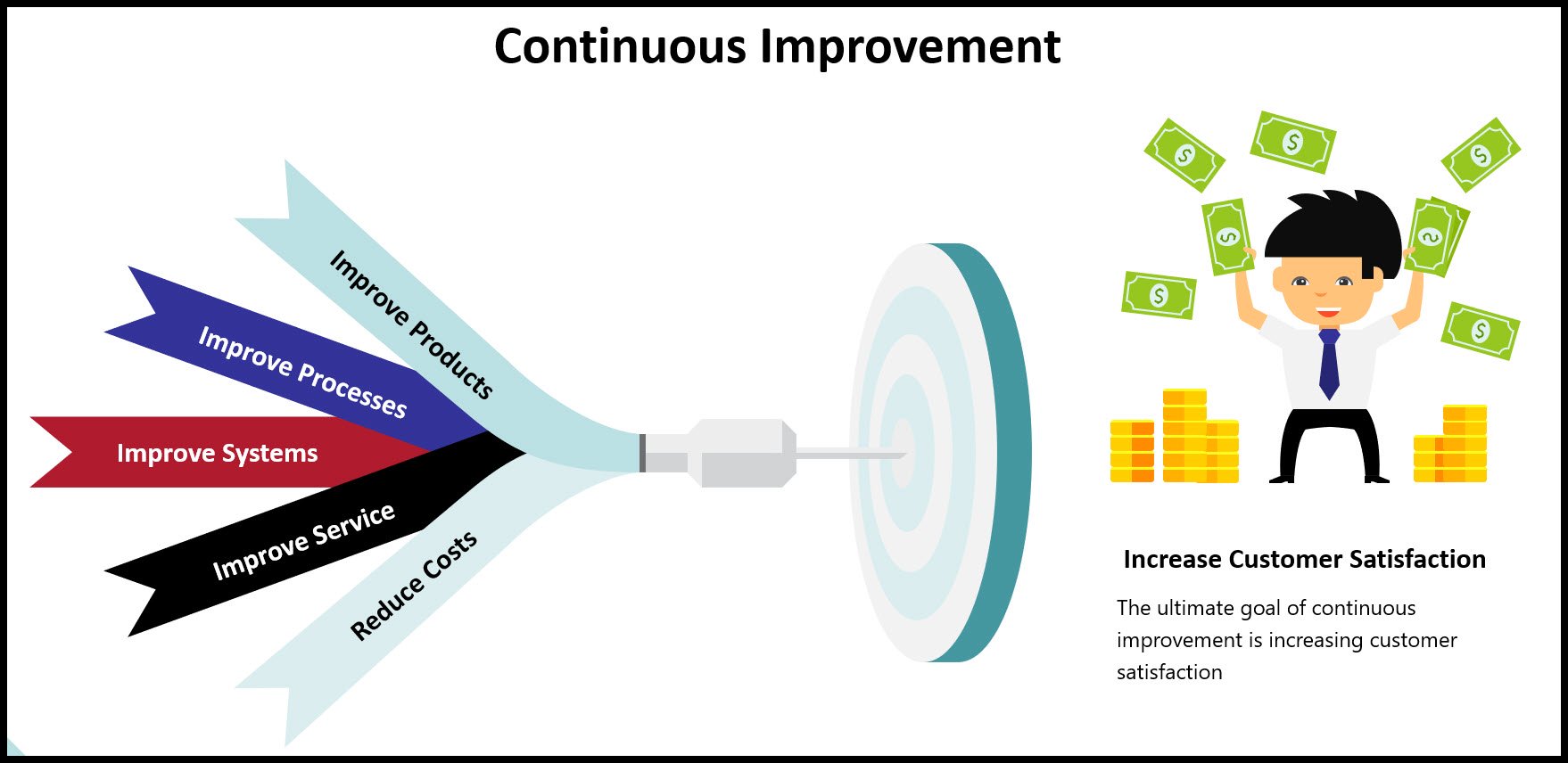

Takt Time is an important Lean calculation

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |