SMED

SMED stands for Single Minute Exchange of Dies and was devised by Shigeo Shingo. It is a key component of rapid changeover

During the period between 1950 and 1969 three Japanese companies, Mazda, Matsuzo, and Toyota developed SMED. Since then this tool revolutionized the entire automotive and metal fabrication industries. Not only effective in all discrete-manufacturing industries, but this tool equally applies to most service industries. Useful in health care for room cleaning and turnover or in hotels where the room turnover occurs between the noon checkout and the 3 p.m. check-in time.

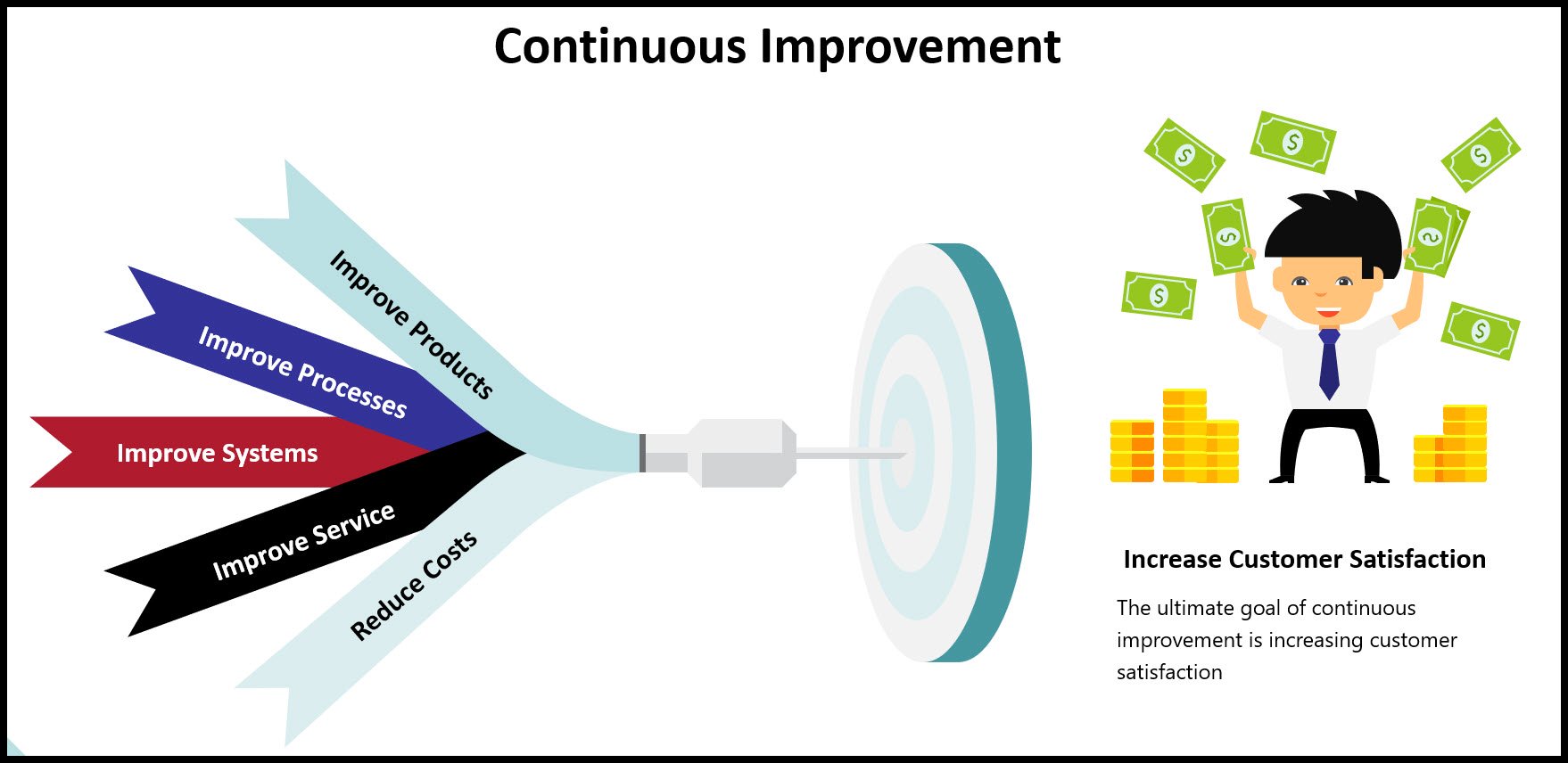

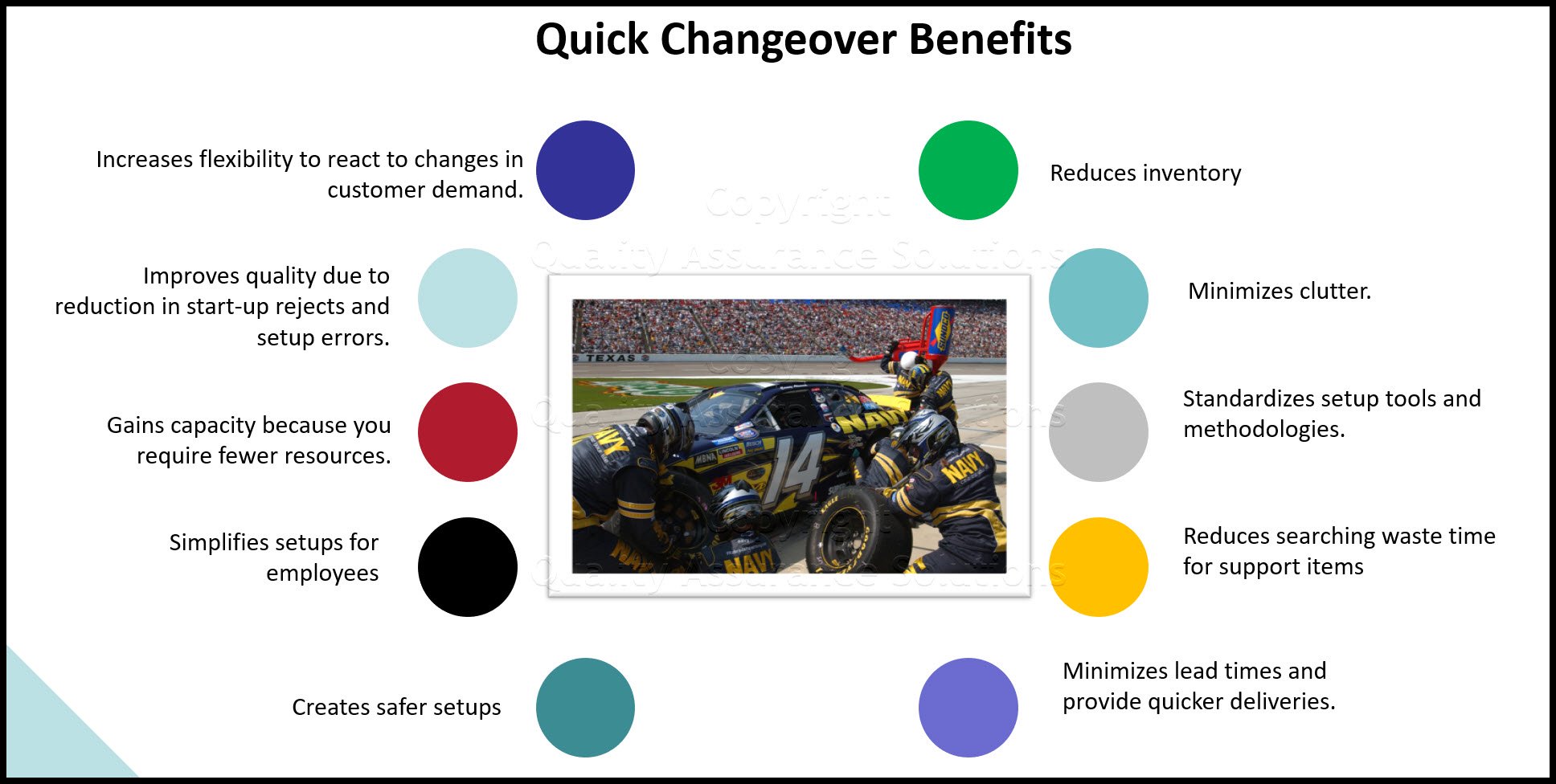

By reducing changeover times, businesses gain significant benefits from reduced costs per unit, lot sizes, process lead time, inventory costs, and setup errors. Businesses also gain increased capacity (and therefore reduction in the need for excess capital equipment), yield, quality, and safety. More consistent, effective changeovers and setups also simplify scheduling by creating a more predictable process.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Measuring Changeover Time

Changeover time is the actual clock time, not labor time or work content. You can easily measure this by starting a stopwatch at the commencement of the changeover and stopping it at the completion.

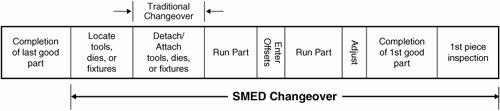

Traditionally, changeover is often considered just to be the tool change time when in fact the lost time is much greater and is better defined per the below figure.

An example machine changeover in discrete manufacturing industry.

The SMED changeover time is the time between the end of the previous run last value added step to the beginning of the first value-added step of the next run.

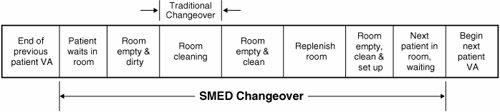

Below shows an example of a SMED changeover for a hospital treatment room. Traditionally we consider the changeover just to be the room cleaning but the actual lost time is much greater.

An example of changeover for a hospital Treatment or Operating Room.

The reasons for long SMED changeovers stem primarily from inconsistency and lack of ownership. Individual operators often do changeovers as they see fit, based on their own experiences and no two operators changeover the same way. Often operators on one shift are not comfortable with a changeover or setup done on a previous shift. Therefore, changeovers are repeated and some operators even think that quality is better with a longer changeover.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

Logistics

When implementing changeover reduction in an area you typically plan an event. The event duration is anywhere from one day for a small piece of equipment to perhaps a 45 day event in a larger more complex process.

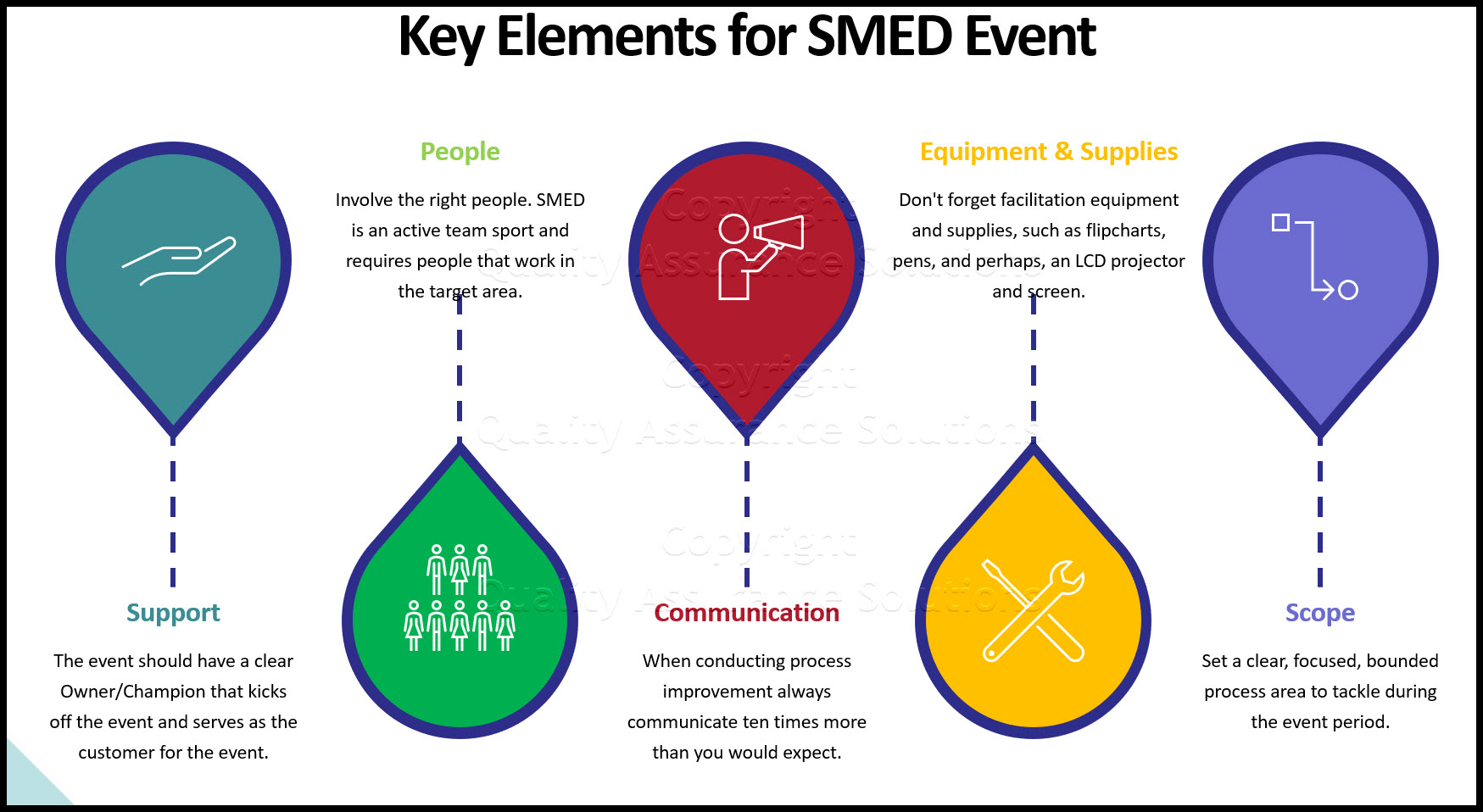

Key Elements for the Event

Support. A SMED event is not a small affair and will likely make a significant change. This requires solid leadership support to ensure success. The event should have a clear Owner/Champion that kicks off the event and serves as the customer for the event.

Scope. When conducting an event, scope creep causes the biggest failure. So set a clear, focused, bounded process area to tackle during the event period. Don't be tempted to move beyond this area.

People. Involve the right people. SMED is an active team sport and requires people that actually do the work in the target area. Key functions to involve are

- Operators and supervisors. The most important members of the team are those who actually operate the equipment and perform the changeover tasks.

- Process engineering act more in a support role. They add technical expertise and implement and build on operators' ideas.

- Maintenance are often involved in the changeover event. They provide resources for mechanical ideas and fixture design.

- Quality Assurance quality checks often add significant time to changeovers and so QA involvement can help reduce this time.

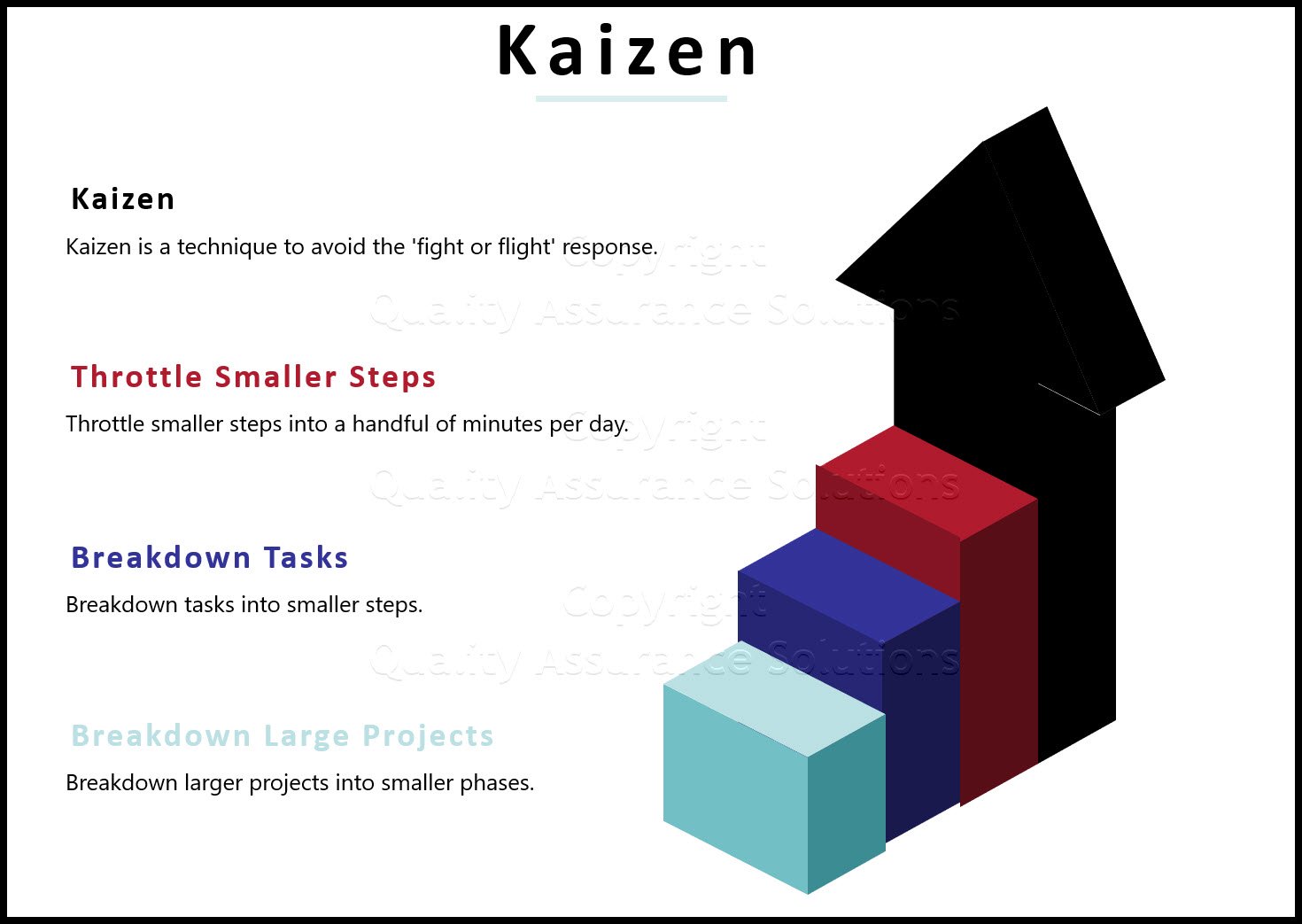

Communication. All parties involved in and affected by the event need to know of its existence and implications to them. The team must realize that work needs to be done there and then rather than be put on a to-do List for future change. SMED follows the Kaizen mentality of doing it today, instead of planning it to be done over a period of weeks; hence the need for strong leadership support. When conducting process improvement always communicate ten times more than you would expect.

Equipment, Supplies, and Ancillary Items.You conduct most of the event in the process area itself. Set up another quiet area to train the team briefly on the SMED process. This area also serves as a work area at times through the event. Don't forget facilitation equipment and supplies, such as flipcharts, pens, and perhaps, an LCD projector and screen. Consider videoing the changeover before and throughout the event to further analyze the activity. Ideally, use one video camera per changeover operator. You may likely work on re-laying out the area so include an enlarged blueprint or CAD drawing of the process.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

SMED Roadmap

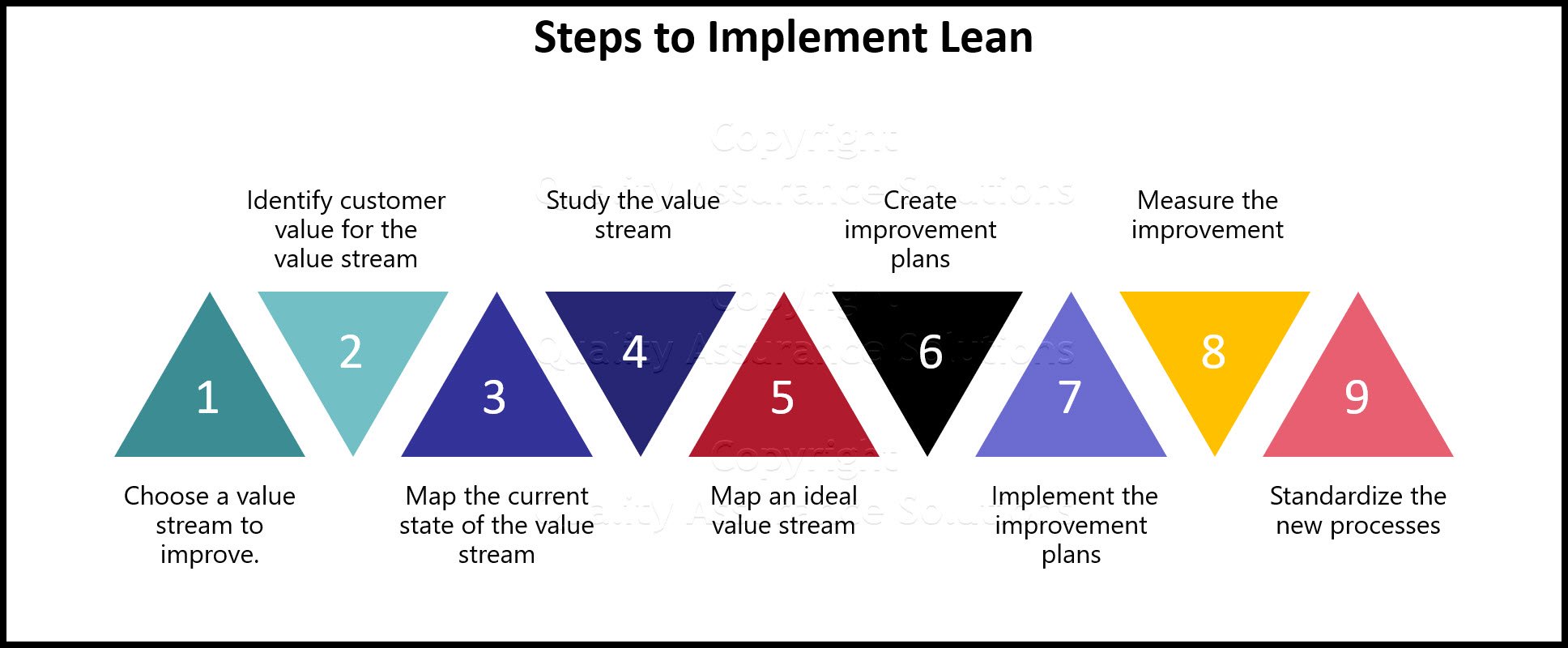

Step 1

Baseline current performance. Establish an accurate baseline for changeover downtime with enough detail to make a distinction between setups, changeovers, and other downtime. If this data is not available historically, then it can be calculated approximately from Step 2 along with the number of changeovers made in a period.

Step 2

To prevent missing important details use a video camera to gather changeover data. Record the changeover in one sitting, so use a separate camera to record each operator in parallel. Focus on the details of the changeover activities as much as possible. Don't be tempted to set up a tripod, leave and then come back on the completed changeover. You may lose details.

Make sure the cameras have on-screen timers. If not, then put a large digital clock in a strategic location to track the time. Be sure to inform the operators about the video recording ahead of time.

Step 3

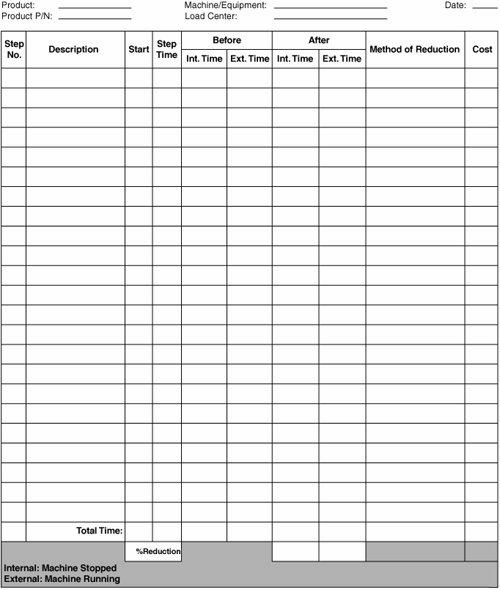

Analyze the video recordings. Document the changeover with the operators. Complete the first four columns of an SMED Time Analysis Chart for the changeover, as shown below

Step 4

Classify the current changeover steps into internal and external time

Internal Operations are performed only when the machine is not running. Examples include changing a fixture on a machine or changing a bed for the next patient. Place the step time for internal operations in Column 5 in the SMED Time Analysis Chart.

External Operations might be performed while the machine is running. Examples include organizing tools, preparing new fixtures, getting material, and so on. Place the step time for external operations in Column 6 in the SMED Time Analysis Chart.

Identifying the tasks currently being performed as internal operations, but could potentially be completed externally, is a key to reducing changeover time.

Step 5

Generate ideas to reduce the changeover time using the SMED Time Analysis Chart. There is no prescriptive approach here, see the below for possible change over reduction solutions.

Step 6

Create the Improvement Plan. Document the team's ideas and form two project lists. Create a short-term action list that can be completed immediately with little or no capital requirements. All action items should have clear owners and due dates. Create a long-term projects list that are more involved and might require capital and equipment modifications. Project owners should be allocated.

Your ISO 9001:2015 Kit includes Templates, QA Manual, Implementation Guide and a Gap Assessment Internal Audit Tool for ISO 9001:2015

Step 7

Execute the improvement plan to install the new changeover process.

Step 8

Control the new changeover process. Write new changeover procedures and best practices. Provide training across all shifts to standardize the new setup procedures. Document and publish the results of the new changeover process. Continue tracking changeover time to monitor the results.

Step 9

Proliferate this event to other machines or work-centers. Implement these best practices across all machines. Focus on bottleneck areas first.

Ideas for Reducing Changeover Time

Move internal items to external by doing the following:

- Using pre-setup activities

- Tools cleaned and sharpened

- Gages preset and supplies ready

- Materials transported and sequenced

- Tools, fixtures, and supplies positioned

- Paperwork organized and prepared

- Using post-setup activities

- Clean, inspect, return, and repair tools, materials, and fixtures

- Store all items in assigned locations

Divide the changeover activities by resource and apply Critical Path Analysis to each resource. On the Critical Path strive to do the following:

- Eliminating all non-value activities

- Eliminating or reducing other activities

- Moving activities off the Critical Path

Improving organization by the following. Note that 75% of the reduction can come from organization and 5S.

- The area is sorted and cleaned

- Place all necessary tools nearby. Use shadow boards for hand tools

- Post paperwork and checklists in the area

- Visually identify all stages of production through the work through area. Clearly identify incoming and outgoing lots near the area

- Use dedicated tool or die carts for each machine

Your comprehensive package for learning and training the TRIZ problem solving methodology. Includes mobile app, books, PowerPoints and real world examples.

Organize people in the work area before a changeover:

- After a changeover begins, the participants should never leave the area

- Everyone and everything involved with the setup is waiting for the machine to shut down

- All operators follow a routine

- Make someone accountable for preparing changeover kits prior to the changeover.

Reduce or remove elements in the changeover by doing the following:

- Using one-touch equipment exchange (no adjustments, only touch the equipment once)

- Using clamps or quick-release devices to attach tools, fixtures, air and water leads, and so on

Eliminate adjustments and trial runs. Adjustments and first articles can account for as much as 50% of changeover time. Strive to eliminate them completely, not just reduce the time taken to perform the adjustment.

- Break the practice of running equipment, testing it, adjusting, running more trial product, and so on. Spoil product during setup.

- Replace infinite adjustments with mechanical stops. Design fixtures, tools, and associated equipment so that they are self-positioning.

- Using digital readouts instead of dials and manual measuring tools when adjustment is absolutely necessary.

Standardizing the area with the following:

- Determine which entities run on the machine, then evaluate the equipment to see if it can be modified to serve each without changeover.

- Determine the tools, tool holders, and supplies being used. Then evaluate each to see if one can replace several.

- Standardize size often. This allows the use of common fixtures, dies, and tools.

- Standardizing all fasteners (size and type) on all fixtures.

- Determining if gauges used can be standardized or simplified.

Simplifying the area by the following.

- Using fewer parts during setup by combining functional pieces.

- Make it obvious when the setup is complete and correct (stops, gauges, and so on).

- Create pre-kits of all non-standard tools and store in staging area.

- Ensure tool kits are clearly marked with part numbers.

- Ensure information on supplies sheets are up to date.

- Simplify mounting and removal of dies, fixtures & chucks.

- Arrange all tools and supplies at point of use, by frequency of use. Operators should not have to move or turn frequently for tools.

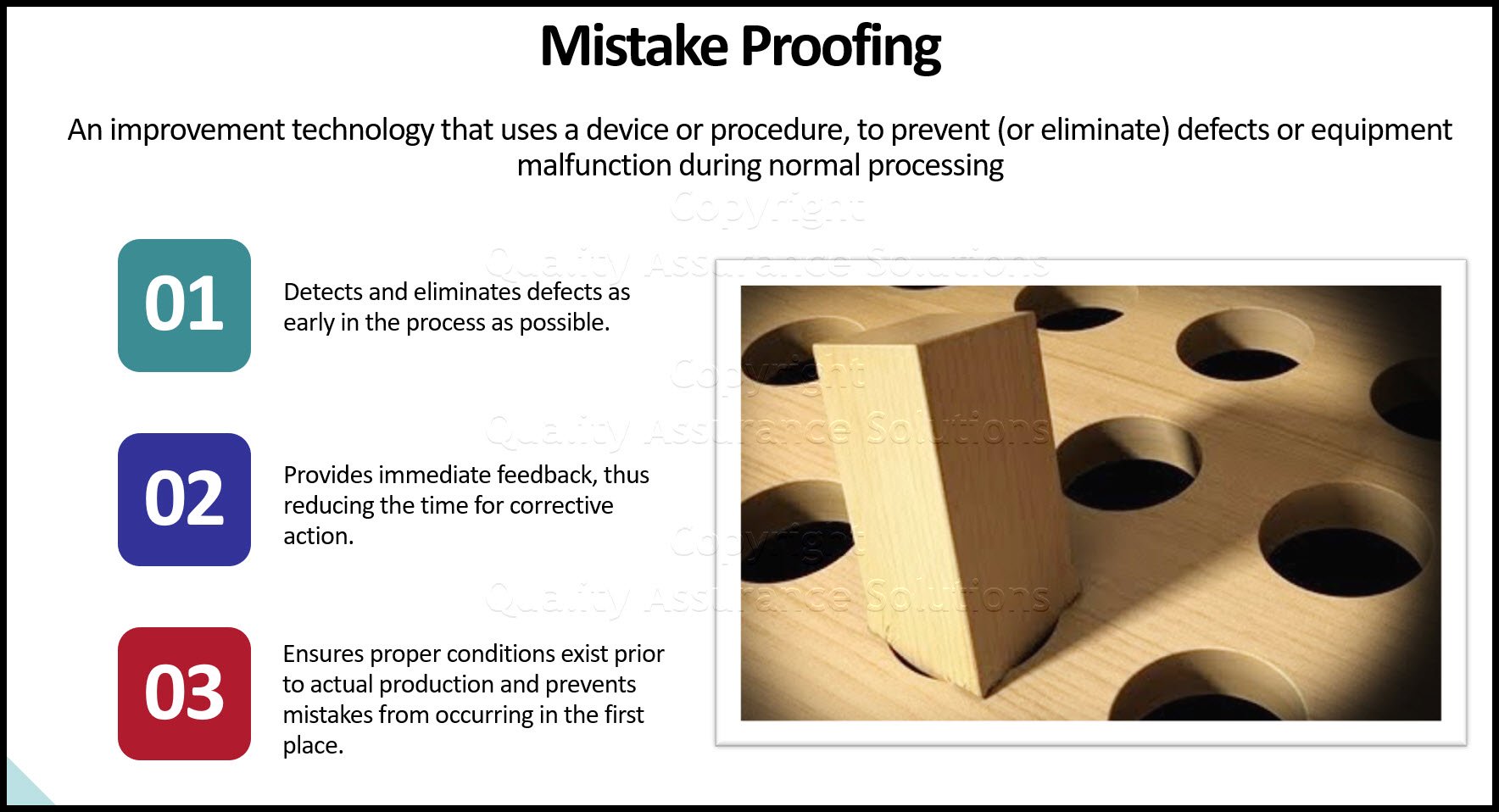

Implement mistake proofing

- Use color coding and marking on all standardized tools, fixtures, jigs for identification.

- Use pins, blocks, or stops for quick alignment.

- Use preset stops, limit switches, light switches, and proximity switches.

- Use total productive maintenance principles to ensure that all tools, dies, materials, and supplies are defect free and working properly.

Problem solving. Things not happening or working the way they were designed causes time wasting issues during a changeover. Eliminate these issues altogether. View anything that stands in the way of a perfect, trouble-free setup as a problem

- Missing or bent fixtures

- Unsharpened, worn, or misplaced tools

- Out-of-specification supplies

- Mechanical failures

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |