Lean vs Agile

Which Process Methodology Is

Best For Your Industry?

Lean vs Agile...Conventional wisdom says that the Lean methodology is best for repetitive, sequential tasks that produce tangible goods while Agile is better suited for creativity and on-the-fly improvements geared towards software development but is this really the case?

And which methodology is best suited for your business’s processes?

First, let’s examine the differences between the two then consider the similarities.

Lean vs Agile, What is Lean?

Lean Methodology has been around since the 1940s, born from the approach to quality first presented by Dr. Charles Deming for automobile manufacturing and then quickly spreading to other areas of operations.

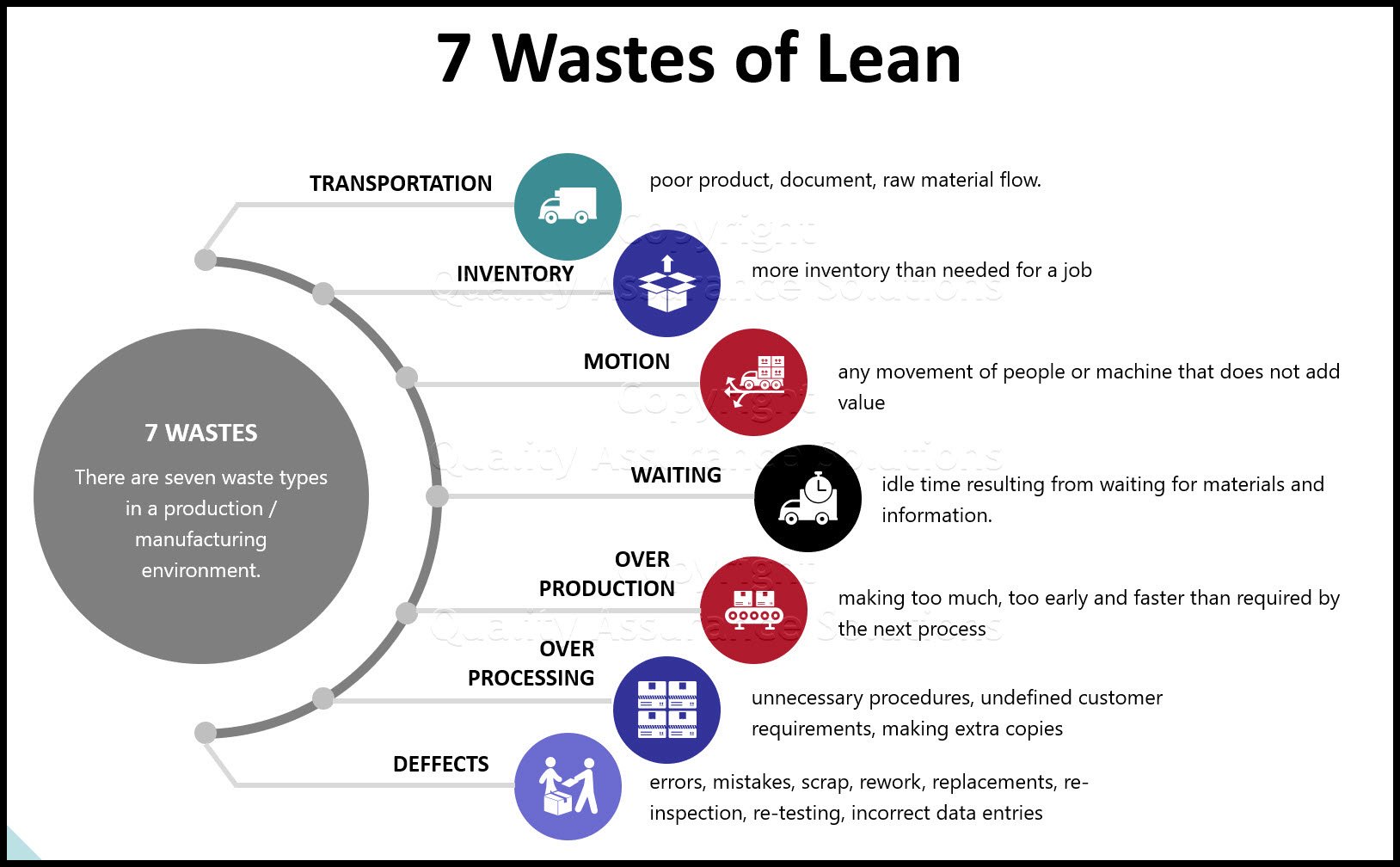

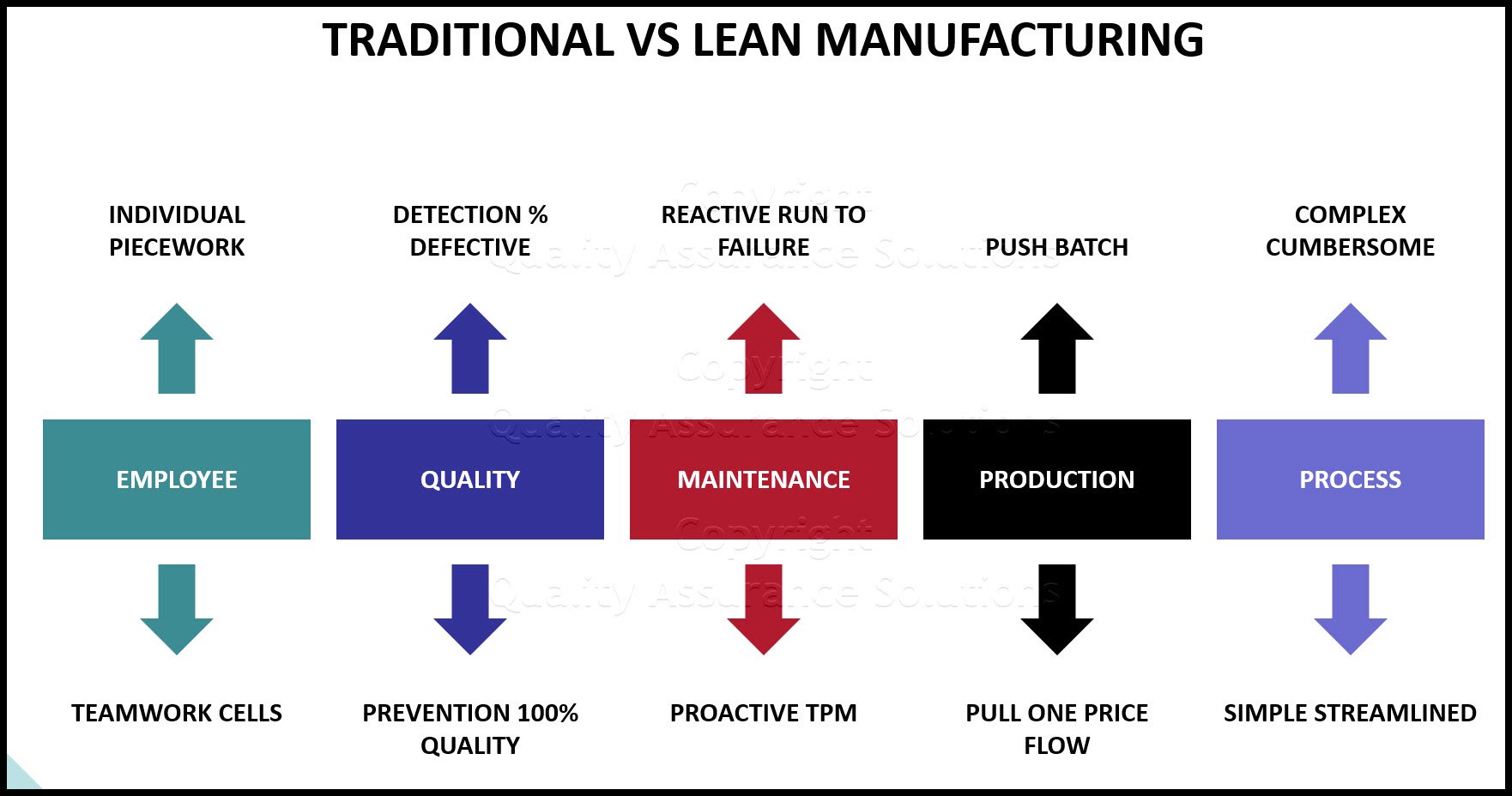

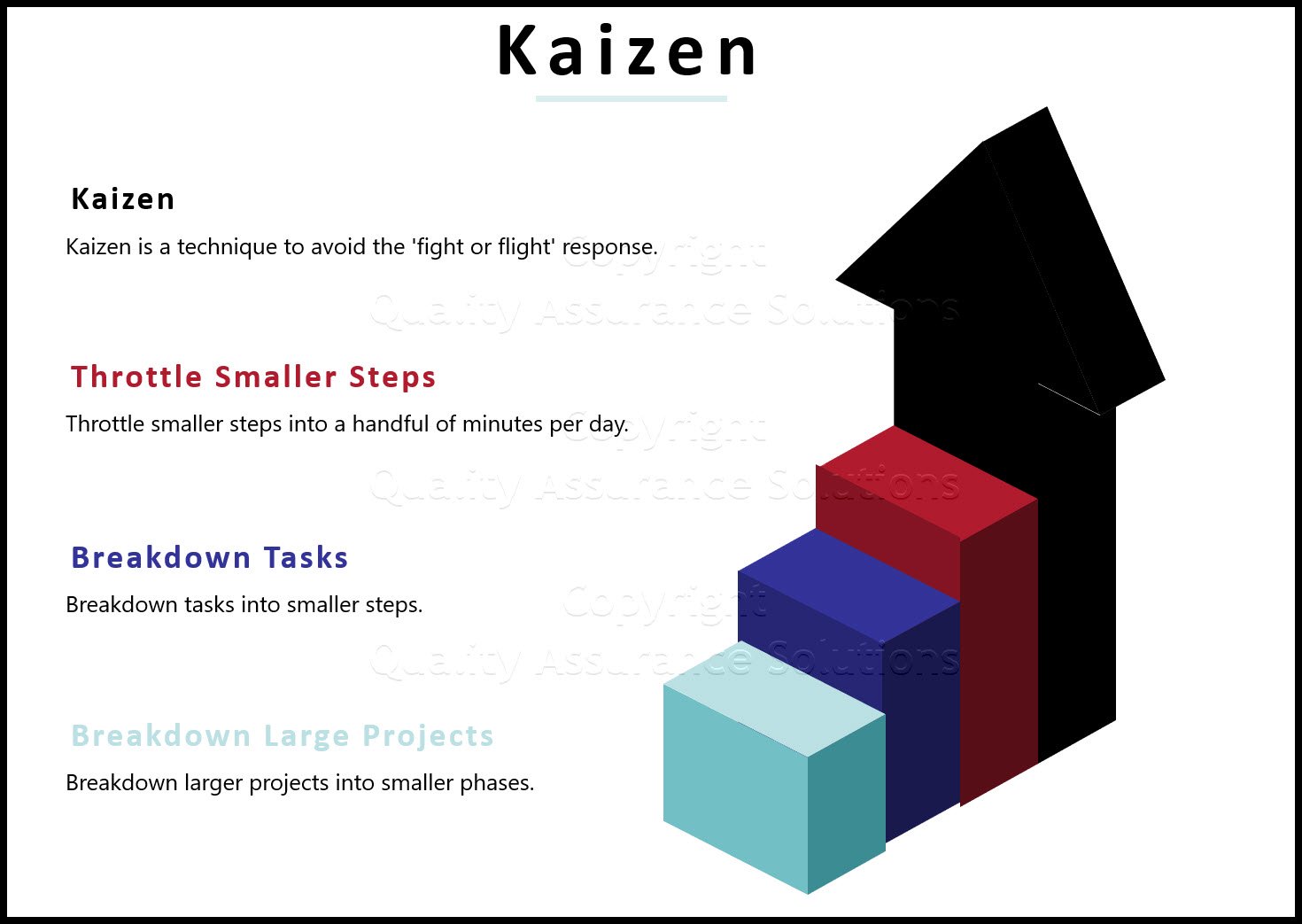

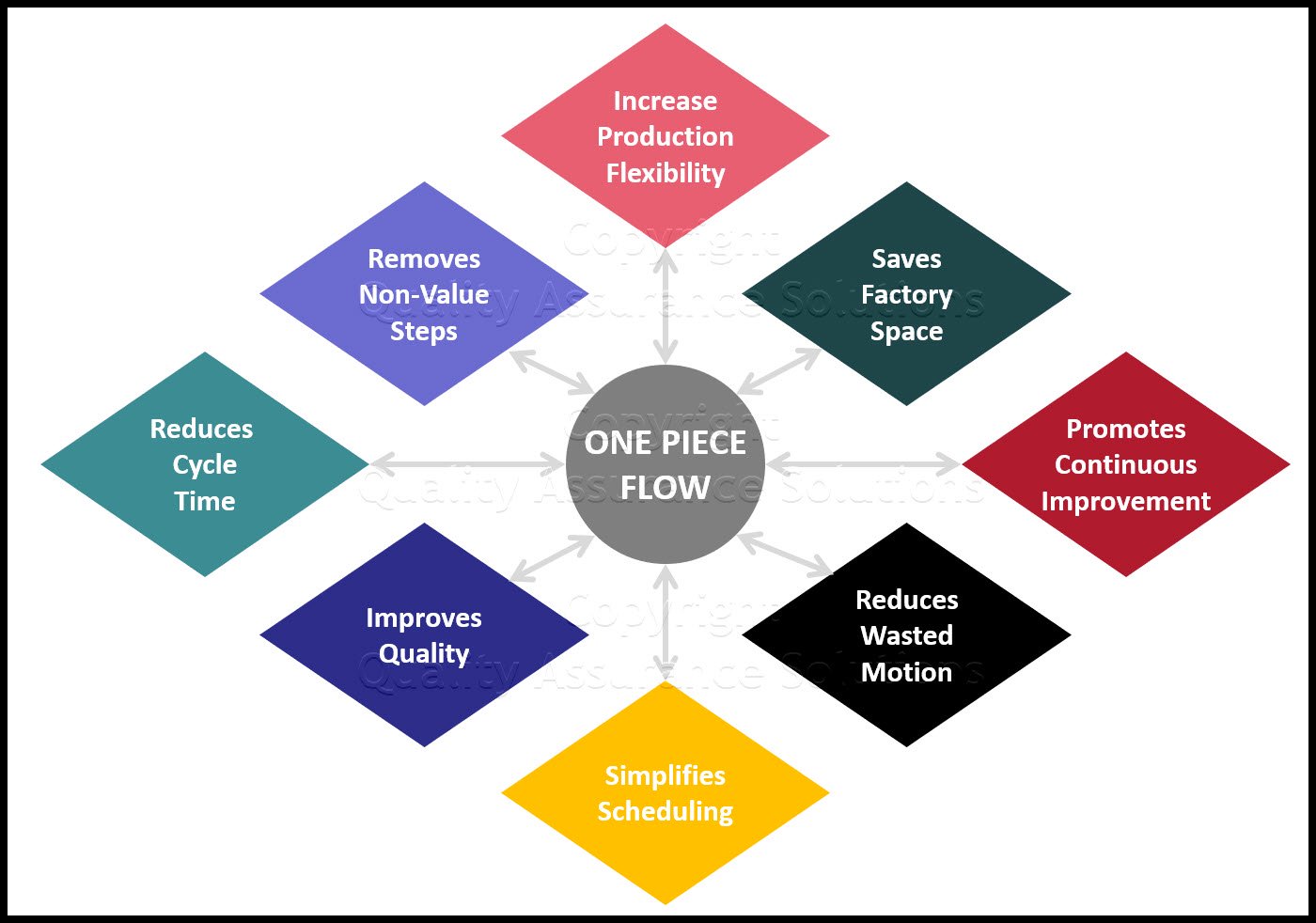

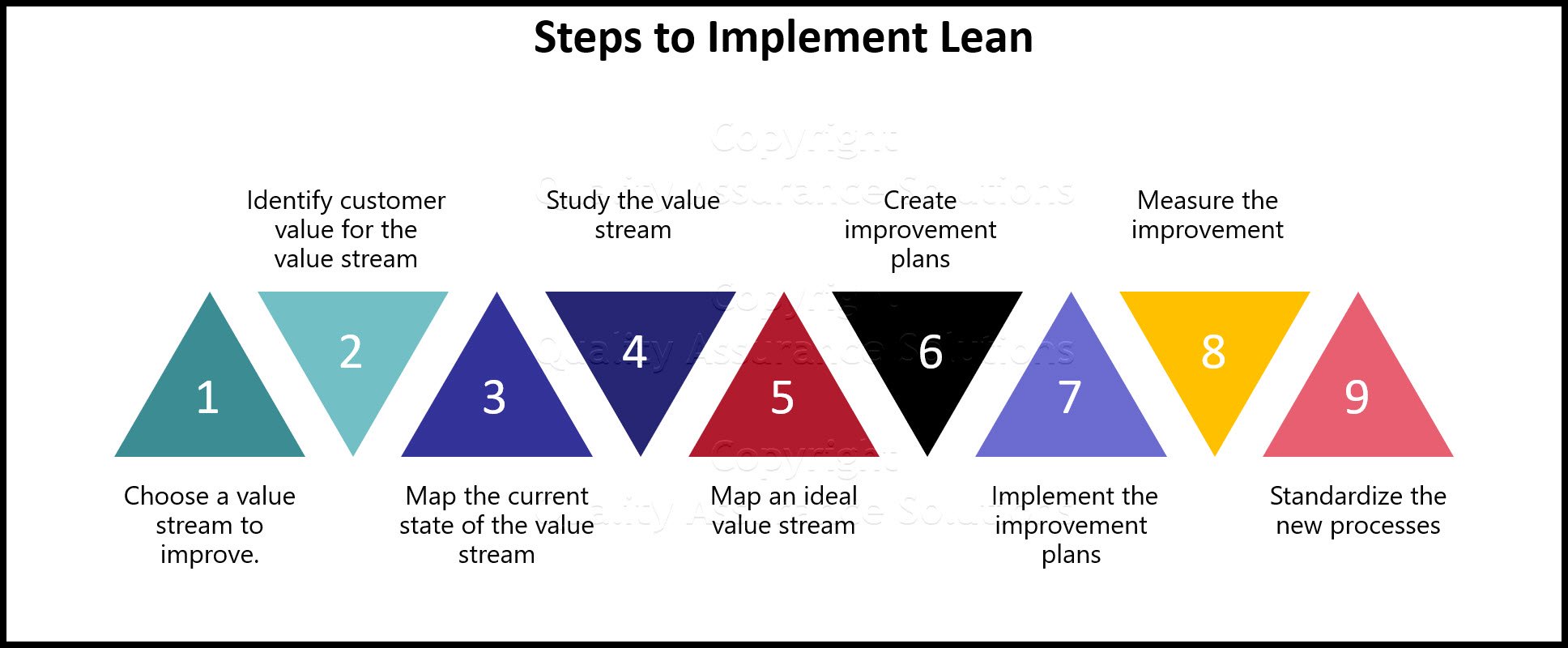

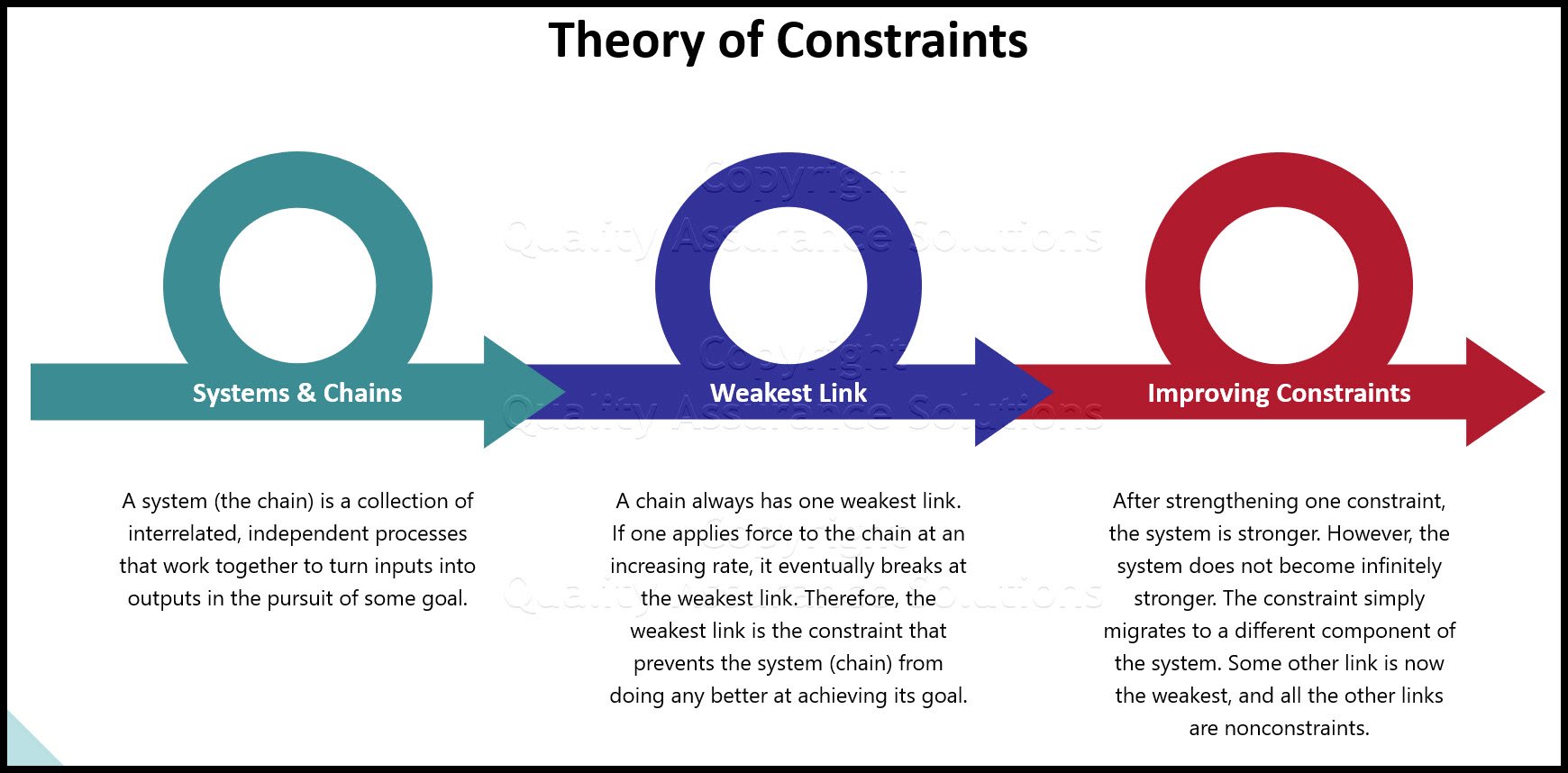

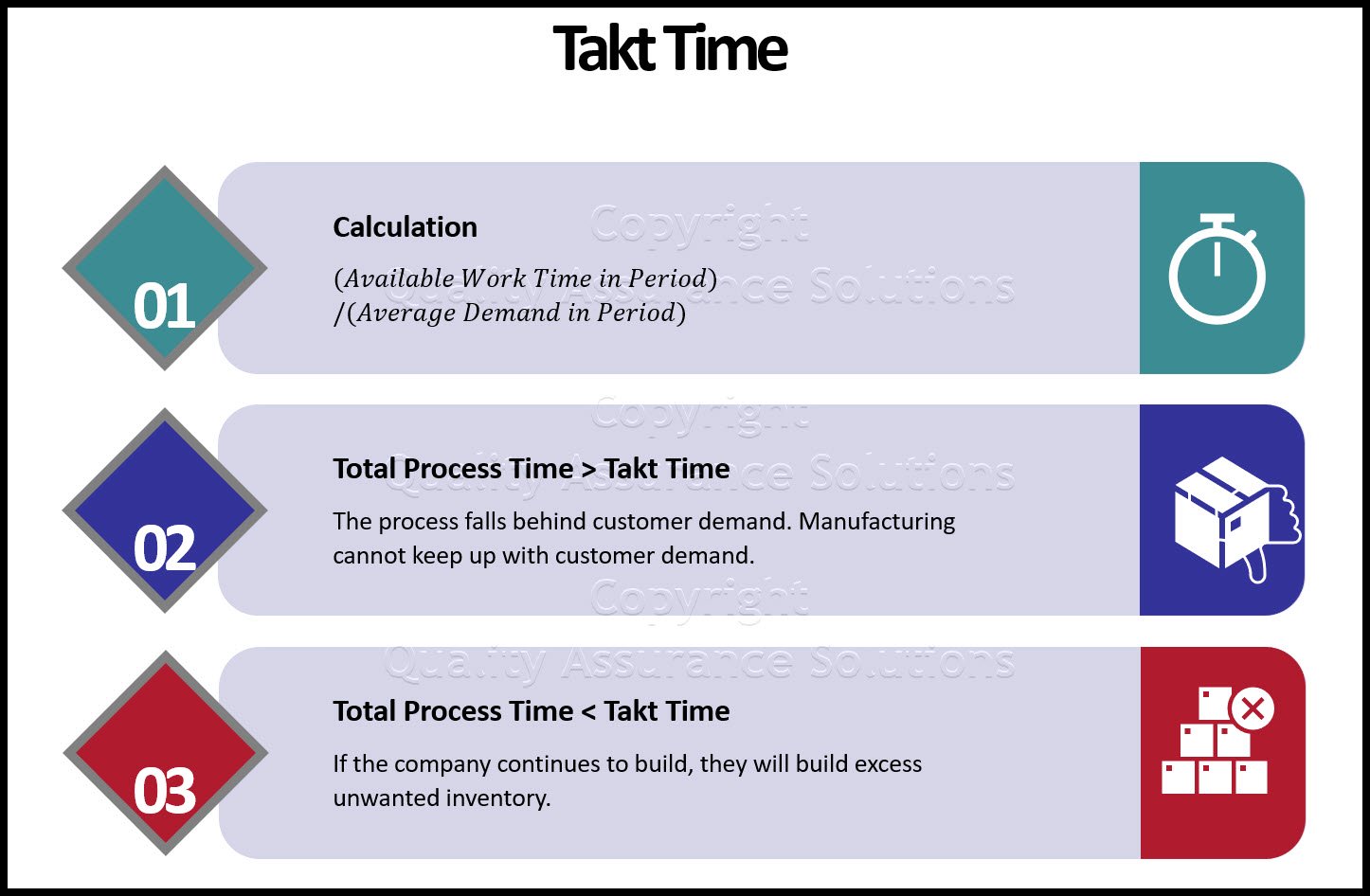

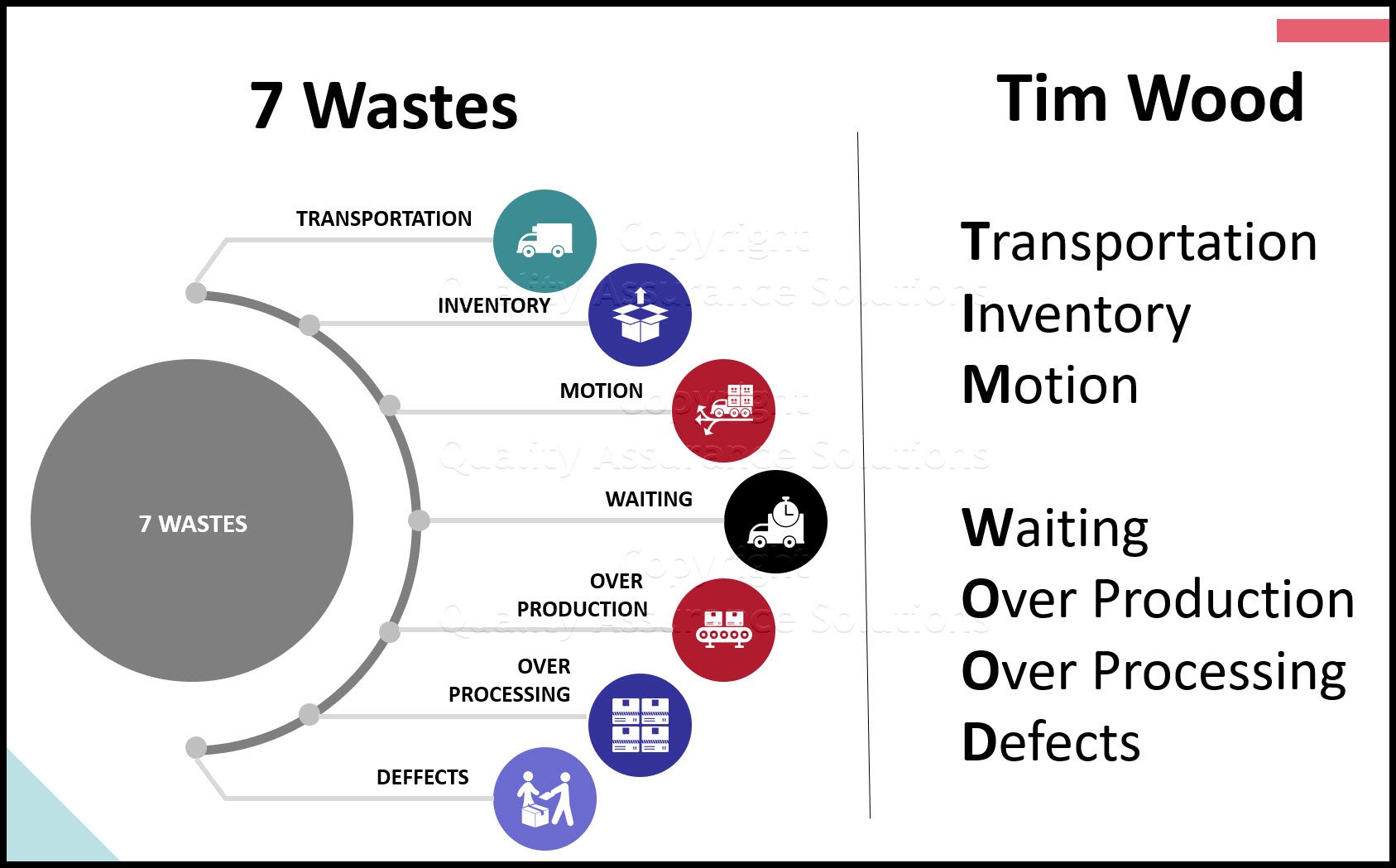

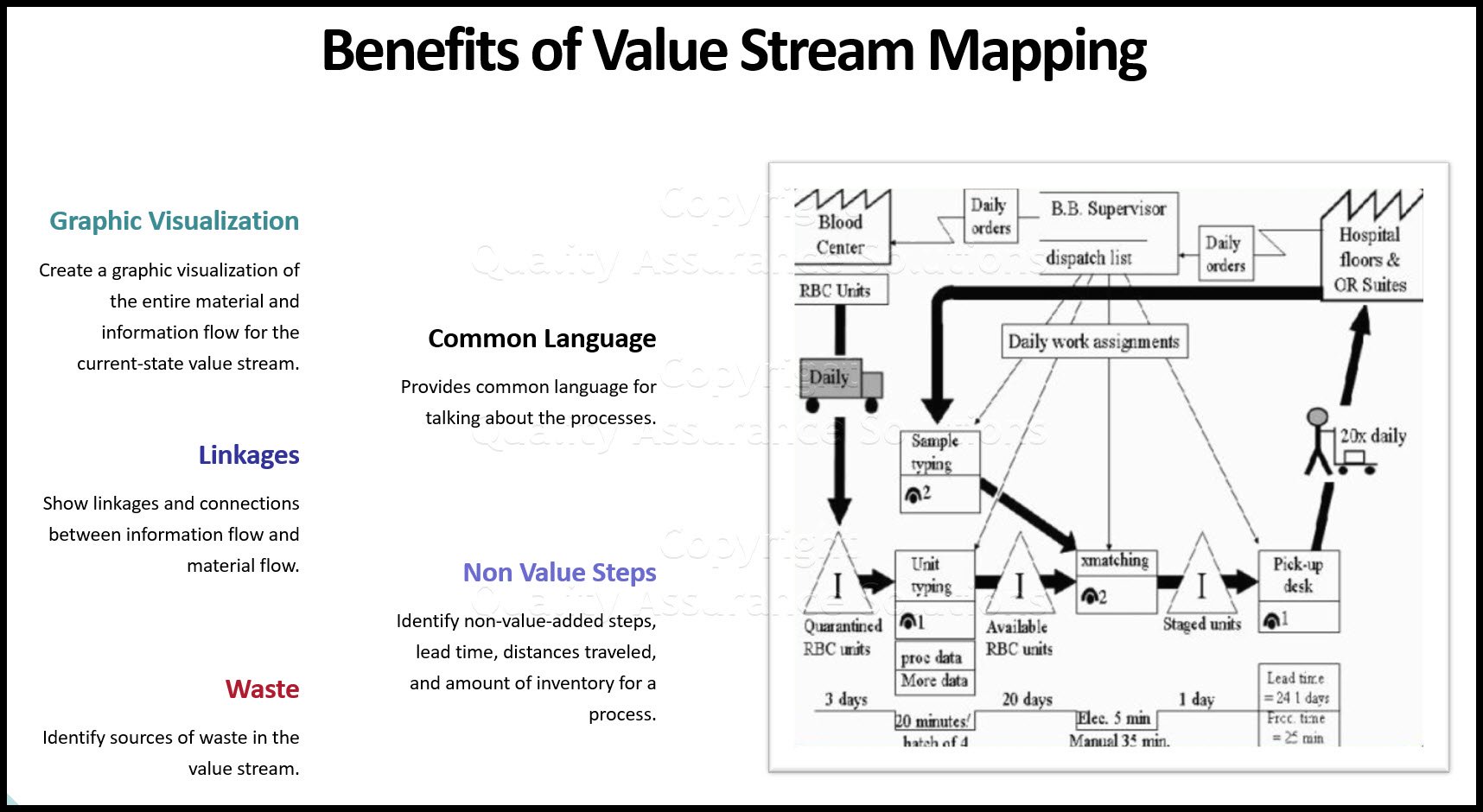

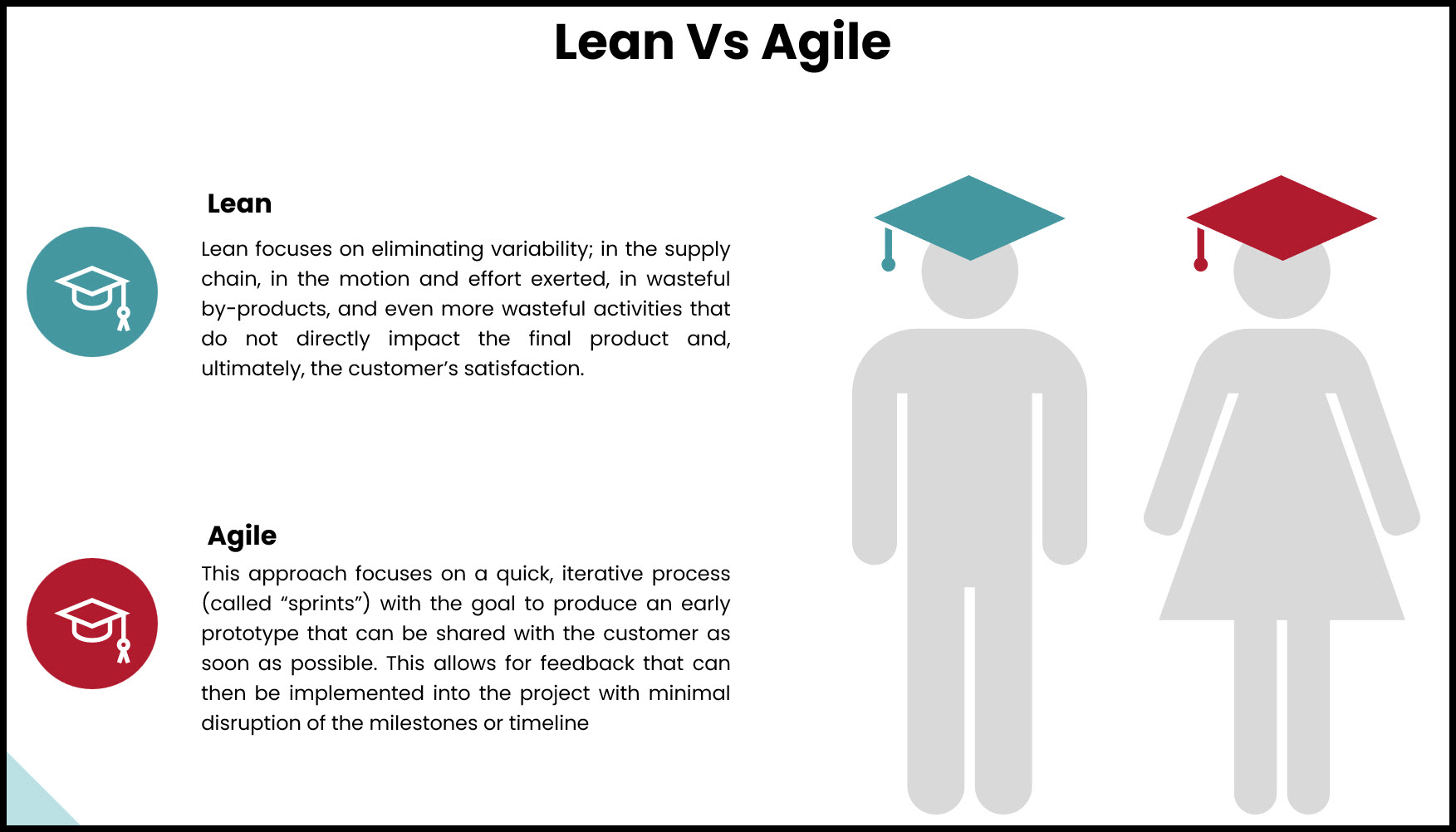

Lean focuses on eliminating variability; in the supply chain, in the motion and effort exerted, in wasteful by-products, and even more wasteful activities that do not directly impact the final product and, ultimately, the customer’s satisfaction.

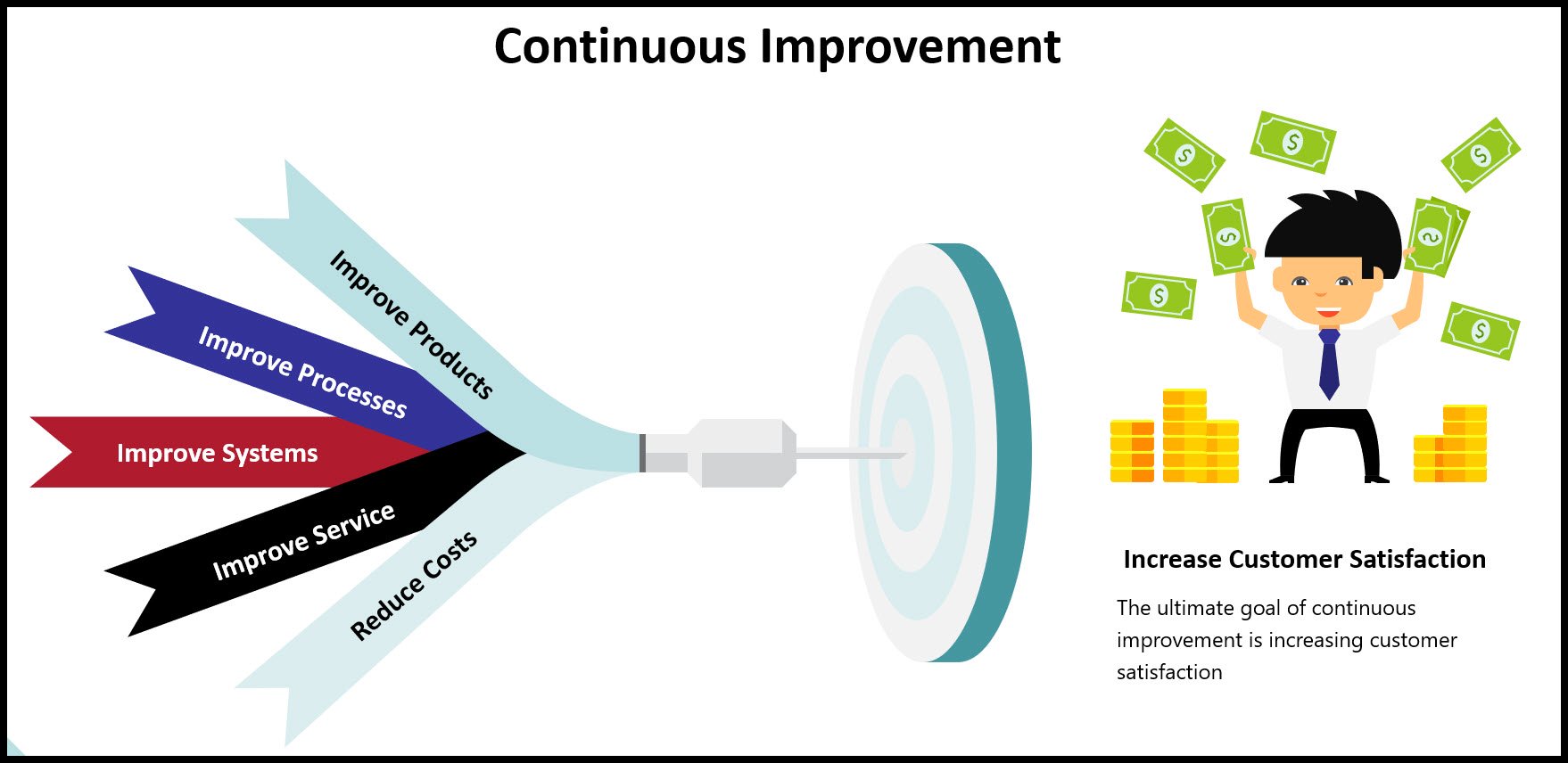

Employees in this environment question any activity that does not clearly add value to the end results. This inevitably leads to a cycle of continuous improvement as inefficiencies are driven out of the process.

PDCA Complete is an organizational task management system with built-in continuous improvement tools. Includes projects, meetings, audits and more.

Built by Quality Assurance Solutions.

An Example of Lean Process Improvements: McDonalds

You can see an excellent case study and example of the Lean Methodology in the movie The Founder, now streaming on Vudu. Based on the creation of the McDonald’s fast-food empire by Ray Kroc, the story details how Kroc took a local hamburger stand that could quickly deliver a hot meal to its drive-up customers to the world’s largest franchise.

Kroc saw the advantage of standardizing what had traditionally been a one-at-a-time, often chaotic assembly of a product (in this case, a simple hamburger) which greatly sped up the entire process and drove out inefficiencies in the cooking and delivery systems thus saving the establishment money on supplies and staffing.

What is Agile?

Agile first used in the development of software in the early 1990s, quickly accelerated after 2001 as it expanded into other industries including manufacturing.

This approach focuses on a quick, iterative process (called “sprints”) with the goal to produce an early prototype that can be shared with the customer as soon as possible. This allows for feedback that can then be implemented into the project with minimal disruption of the milestones or timeline.

The short sprints, which can be anywhere from a few days to four weeks, and the self-organizing teams allow quick changes to requirements without negatively affecting the schedule.

Agile also empowers the team to make design decisions without a complex approval process, speeding up the development even more.

Get certified to Scum Agile Project Management with our comprehensive on-line courses. Fully Accredited + PMI units

Which Methodology Is Best for Your Business?

While the descriptions above seem to indicate significant philosophical differences between the two methodologies, the goal of both is to deliver the highest quality output in the most efficient manner.

Meeting customer expectations and delighting the customer remains the primary focus, regardless of the method. This leads us to the ultimate question: Which process is better -- Lean vs Agile?

Both methodologies offer tremendous value for many different types of businesses (not just automotive or software), but one is typically better than the other for your specific project.

This could even change for different projects within the same organization but, in general, Lean methodology should be the preferred choice for businesses working with physical goods (such as manufacturing) while Agile methodology delivers an excellent choice for people working with digital products and software code.

In reality, the real answer to the “best” choice may be somewhere in between. A hybrid or blended approach can leverage the benefits of both and be applied at different points in the timeline.

One of the key benefits of Agile is the speed with which a working prototype can be delivered, and this generally holds true. But a prototype that does not require huge modifications or enhancements then lends itself to a more repetitive approach as new or additional features are added and tested which fits the Lean methodology.

For larger projects, experience leaders adept to using both and know when to shift from one to the other. The framework for managing and leading each, while similar, uses distinct terminology, acronyms, measurement techniques, and milestones so being well versed in both is quite demanding.

Summary Lean vs Agile

Nearly any business process can be improved by a wide range of methodologies, but there typically is a best choice for your business based on the products you sell, the availability of resources, the skills sets that can be brought to bear on a project, and the level of expertise in the chosen methodology. A blended, hybrid methodology of Lean vs Agile might be the best choice for your business.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

An Organizational Task Management System. Projects, Meetings, Audits & more | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

450+ Editable Slides with support links | ||

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |