Six Sigma Breakthrough

You might have heard or read about Six Sigma Breakthrough in the newspaper as organization after organization has begun to adopt and implement this powerful management philosophy.

Why The Mass Adoption of Six Sigma:

Companies exist to be profitable. Profitable companies provide jobs and pay taxes that benefit the community. Making a profit is based on having customers who want your product or service. Wanting your product or service is just the beginning.

Every business exists because it has customers. Every customer has a set of requirements. If you meet their requirements, you are being effective. If you don't meet their requirements you are being ineffective. If you are ineffective and do nothing about it, soon you will be out of business.

However, focusing merely on customer effectiveness would eventually mean you could go out of business. Why? Because to be a profitable business, an organization must also be efficient.

Efficiency relates to the amount of resources consumed in being effective. You can measure efficiency in time, cost, labor, or value. Since businesses exist to make a profit, being focused on the customer without also being focused on efficiency would not be a good business decision.

Six Sigma , at its basic level, attempts to improve both effectiveness and efficiency at the same time.

Sigma

Six sigma measures how many unhappy customer experiences per million opportunities.

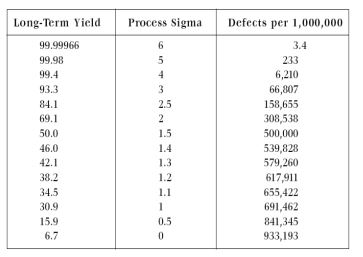

For example, if McDonald's served one million lunch customers, how many of them experienced bad service during lunch? If only three (yes, three) customers were unhappy with their lunch, then McDonald's achieved 6 Sigma on that day. This is because 6 Sigma equal to only 3.4 bad customer experiences for every million opportunities.

So do you think only 3.4 bad customer experiences per million experiences occurred at McDonalds? If 233 bad customer experiences occurred per million McDonald's customers then McDonald's would be a five sigma company. If 6,210 customers experienced soggy french fries or an inaccurate order then McDonald's would be a four sigma company. If 66,807 McDonald's customers opened their lunch bag and found a Big Mac when they had ordered a Quarter Pounder, McDonald's would be a three sigma company.

This concept measures customer satisfaction that is near perfection.

Most companies measure at the two to three sigma level of performance. This means between 66,807 and 308,538 customer dissatisfaction occurrences per million customer contacts. Companies with this level of performance experience business problems. They don't make as much money as they should for their shareholders.

Shareholders get mad and begin to take their money elsewhere. Management wants to increase profitability. Often, they think too much in the short term and begin to lay off employees. What management forgets by downsizing; things only get worse with less people expected to work harder.

Your on-line Lean Six Sigma Certification. Course includes videos, reference materials, mobile app, quizzes and a certification test. Start studying today and get certified at your own pace.

Benefits Of Six Sigma

1-Successful implementation of Six Sigma improved effectiveness and efficiency in the first wave of projects.

2- Greater job security.

3- Learn new transferable skills.

4-These new skills mean greater opportunities such as promotions in your current company.

5- The first projects generate increased enthusiasm and momentum for future activity within your company.

An Example Of Calculating Sigma

In a food ordering process, we collected data on three customer requirements:

1. Food delivery time.

2. Food order accuracy.

3. Food freshness.

For the food delivery time, the food preparation group indicates that the targets delivery for Tuesdays at 6:00 P.M. Further, the group considers a delivery late if the delivery arrives later than 8:00 P.M. and too early if it arrives before 4:00 P.M. This sets the target and specifications. Target = 6:00 P.M. and the specifications being 4:00 P.M. and 8:00 P.M.

We chart the data of delivery performance for 22 previous deliveries. The above chart shows that 11 of the 22 deliveries arrived earlier than the window of allowable time. Two deliveries arrived later than the window of allowable time.

This window of allowable time defines what is unacceptable to the customer. We consider anything unacceptable to the customer in terms of a product or service as a defect.

Use the number of defects to calculate sigma performance. In this example, the 11 early deliveries and the 2 late deliveries are defects. Adding them together we have 13 total defects out of 22 total deliveries. Then we divide 13 defects by the number of units (13 / 22) which equals 0.59.

This means 59 percent of the deliveries are defects. With 59 percent of bad deliveries, then the customer considers 41 percent of the deliveries as acceptable. This number acceptable is called the yield.

The above figure shows a yield sigma conversion chart. A yield of 42.1 percent would equal a sigma of approximately 1.3. Therefore, a yield of 41 percent would be 1.29+ so we round up and call the food service a delivery baseline of sigma 1.3.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |