Dr Deming Point 12

Remove Barriers to Pride of Workmanship

Dr Deming point 12 focuses on improving quality by eliminating barriers to workmanship pride. It's natural for people to take pride in their work. I don't know anyone who lacks that pride gene. Yet the company's management team unknowingly strips employee's self respect by limiting his / her involvement in decisions, process issues and quality improvement.

What is the most important asset within any company? It is not money, It is not machines, It is not the building, It is not the raw or finished goods..It is the people.

TrainingKeeper Software. Keep, organize and plan all your employees' training and activities. Software includes multi-user support with reports, certs, and calendars.

The Barriers

While working with corporate clients, Dr Deming would meet with the workers without the presence of management.

During this meeting he would record the employees responses with regards to quality improvement and the current state of the company. The employees showed frustration with management, they feel powerless to make changes. Even though they were the experts and they understood the process details, they could not make changes to their own processes.

Afterwards, to illustruate Dr. Deming point 12, he shared the recordings with the management team.

Within the meeting, often he found management stress production as the most important business criteria. If workers experienced issues with the production machines, they could not stop the line. They report the machine issues but management showed delay reaction. If the machines still produced parts, sometimes supervisors and managers ignored the reports.

New employees received inadequate training. Another worker trained them and they read poorly written instructions. Engineers wrote many of the instructions, but the complicated instructions language and flow confused the new employees. Instructions lacked pictures, flow charts, and problem resolution details. In addition, management failed to test the employee's competency in these procedures.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

Employees were not allow to inspect their own work and make process adjustments. Instead, QC inspectors judged the employees work. This causes constant rework on the material and slows down the production.

Many times, the workers showed confusion because they did not understand managements' expectations as management constantly change the expectations. The only time they received feedback was during performance reviews. The only time management took notice was during crisis situations.

Management only gets involved when one of these two things occur..

- Production goals are not met.

- Customer complains about a quality issue.

Dr. Deming Point 12 wants to abolished yearly performance reviews. Performance reviews from the workers perspective create fear, reduces communication between management and the workers, and focuses on visible results only. Management uses performance reviews to punish or reward employees. However, these subjective appraisals do not reflect the employee's actual performance.

Deming Point 12 and Empowerment

Barriers to workmanship pride cause low employee morale. Oppositely, employee empowerment breaks down these barriers and increases employee morale. Making employees responsible for quality and quality improvement makes them own the production. When one owns their work, they take pride in their work. Quality improves, production improves, it is a win-win situation.

Empowerment is not easy to implement. Management cannot just say "you are now empowered". It does not work this way. Management needs to provide extensive training for this mode of operation. Management must create company systems that allow for employee empowerment.

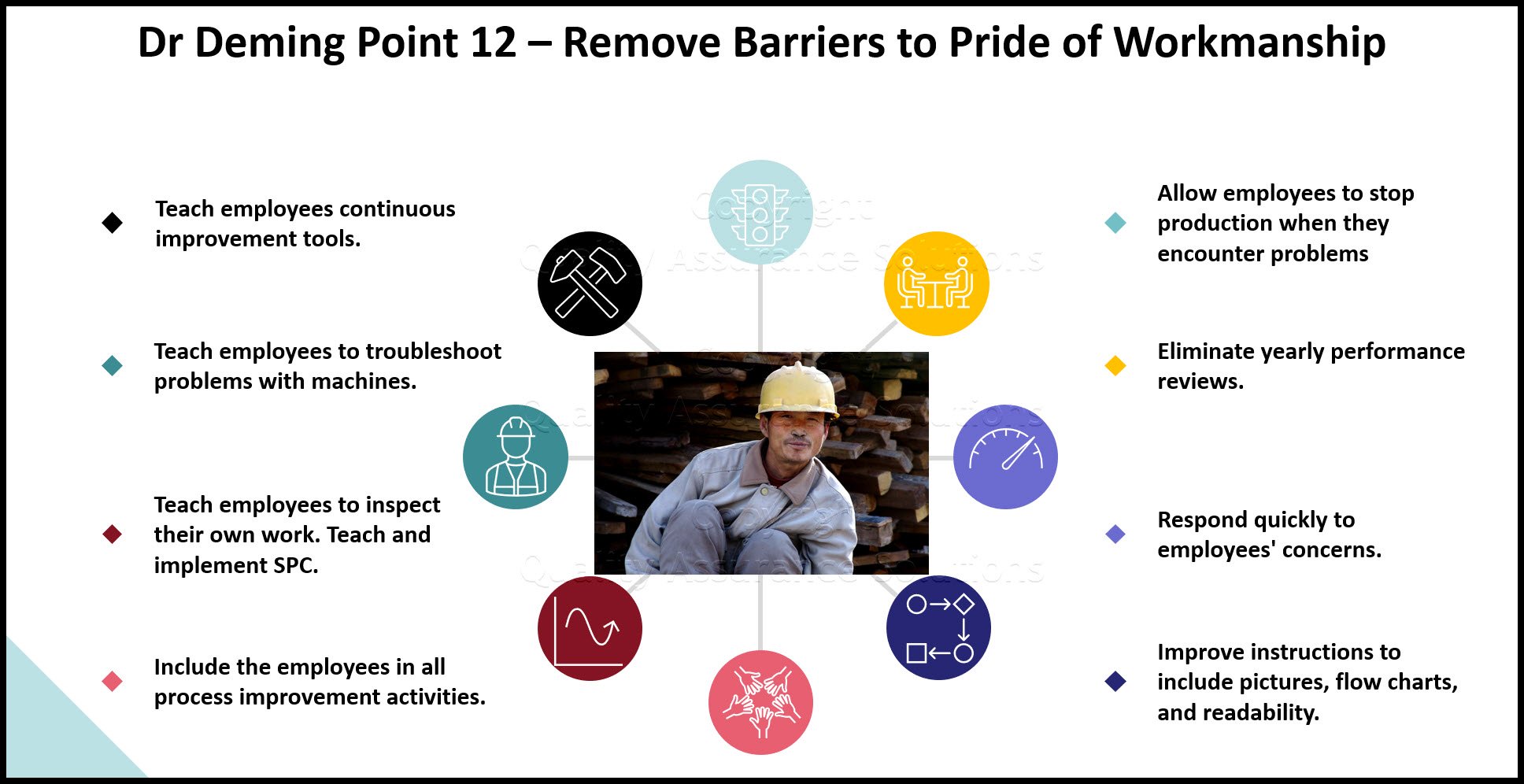

Here is an action list to remove the barriers of pride and improve Dr. Deming Point 12.

- Teach employees continuous improvement tools.

- Allow employees to stop production when they encounter problems.

- Teach employees to troubleshoot problems with machines.

- Teach employees to inspect their own work. Teach and implement SPC.

- Include the employees in all process improvement activities.

- Improve instructions to include pictures, flow charts, and readability.

- Eliminate yearly performance reviews.

- Respond quickly to employees concerns.

- Measure employee competency (by witnessing and testing) and retrain on issues.

Learn SPC in an hour. Train your employees. Improve your processes and products. Prevent defects and save your company money.

Dr Deming’s 14 points

1. Create constancy of purpose for improvement of product and service.

2. Adopt the new philosophy

3. Cease dependence on mass inspection

4. End the practice of awarding business on price tag alone

5. Improve constantly and forever the system of production and service.

6. Institute training

7. Institute leadership

8. Drive out fear

9. Break down barriers between staff areas

10. Eliminate slogans, exhortations, and targets for the workforce.

11. Eliminate numerical quotas.

12. Remove barriers to pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Take action to accomplish the transformation.

|

Quality Assurance Solutions Robert Broughton (805) 419-3344 USA |

|

|

Software, Videos, Manuals, On-Line Certifications | ||

|

450+ Editable Slides with support links | ||

|

Corrective Action Software | ||

|

Plan and Track Training | ||

|

AQL Inspection Software |

|

Learn and Train TRIZ | ||

|

Editable Template | ||

|

Templates, Guides, QA Manual, Audit Checklists | ||

|

EMS Manual, Procedures, Forms, Examples, Audits, Videos | ||

|

On-Line Accredited Certifications Six Sigma, Risk Management, SCRUM | ||

|

Software, Videos, Manuals, On-Line Certifications |